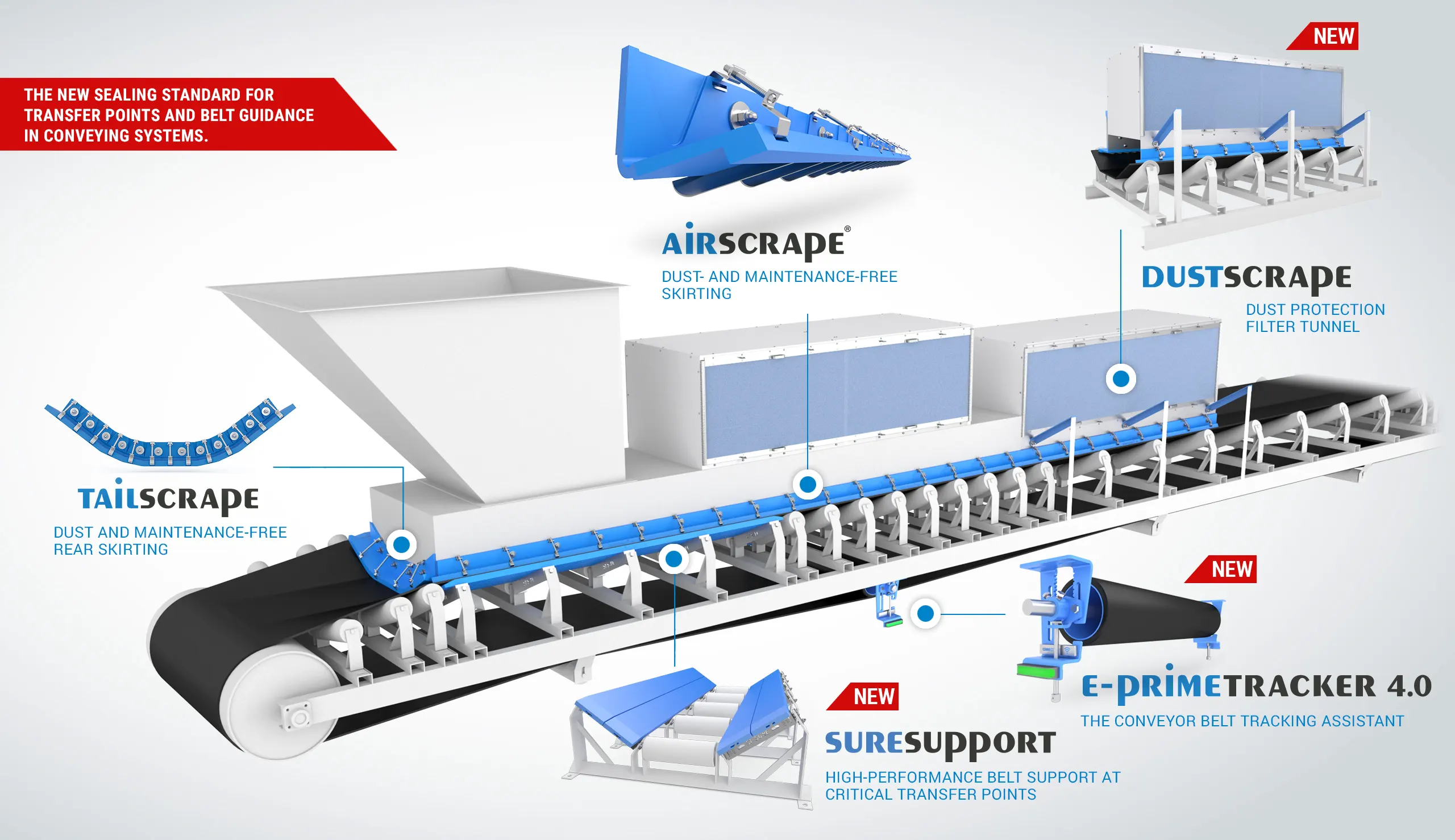

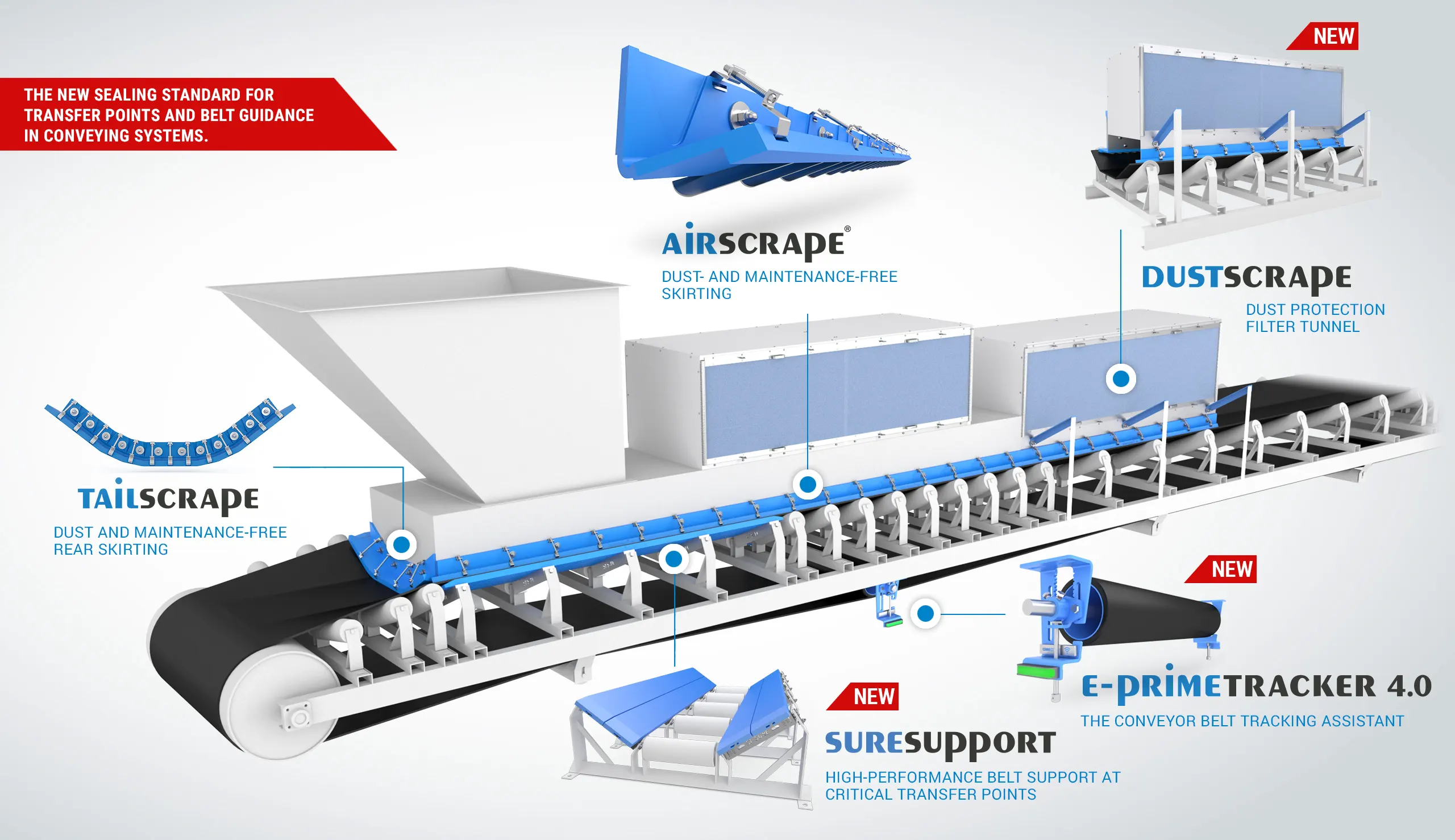

ScrapeTec is positioning itself at bauma 2025 as a strong partner with effective solutions for dust-free and efficient, cost-reducing conveying processes.

ScrapeTec is positioning itself at bauma 2025 as a strong partner with effective solutions for dust-free and efficient, cost-reducing conveying processes.

Fulminant start for ScrapeTec at bauma 2025 in Munich. Time for an short review befor entering the last part.

At this year’s GEAPS Exchange 2025 in Kansas, one topic in particular took centre stage. High dust levels and the associated risk of explosion. Conveyor system operators must optimise their systems in order to minimise safety risks.

The use of unsuitable grain processing equipment can damage the grains. AirScrape reduces and prevents abrasion on conveyor belts and thus ensures that no microplastics and rubber get into the food.

ScrapeTec is positioning itself at bauma 2025 as a strong partner with effective solutions for dust-free and efficient, cost-reducing conveying processes.

Fulminant start for ScrapeTec at bauma 2025 in Munich. Time for an short review befor entering the last part.

At this year’s GEAPS Exchange 2025 in Kansas, one topic in particular took centre stage. High dust levels and the associated risk of explosion. Conveyor system operators must optimise their systems in order to minimise safety risks.

The use of unsuitable grain processing equipment can damage the grains. AirScrape reduces and prevents abrasion on conveyor belts and thus ensures that no microplastics and rubber get into the food.