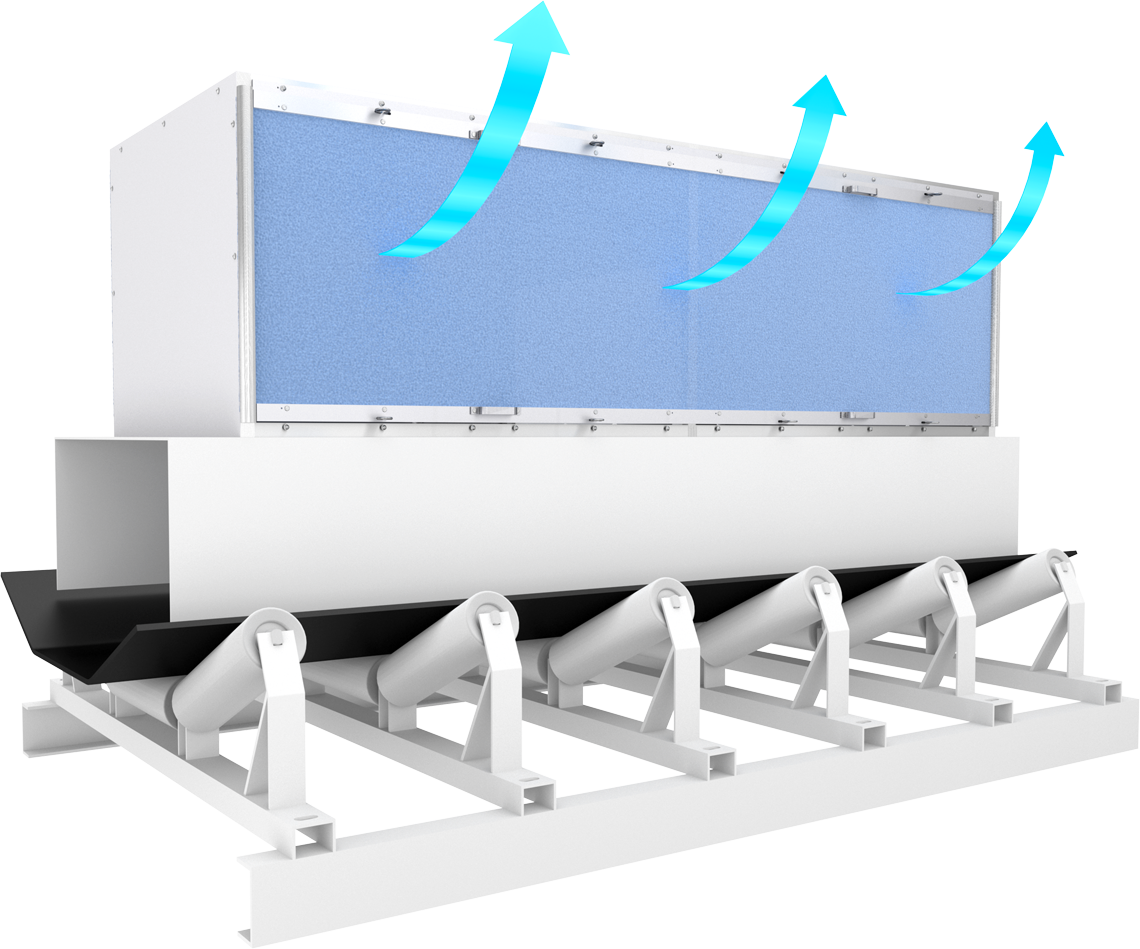

In closed transfer points on conveyor systems, particularly high pressures can occur, resulting in heavy dust formation. The DustScrape has been specially developed for such complex dust filtration problems and solves them particularly effectively.

Highly effective against dust formation

In closed transfer points on conveyor systems, particularly high pressures can occur, resulting in heavy dust formation. The DustScrape has been specially developed for such complex dust filtration problems and solves them particularly effectively.

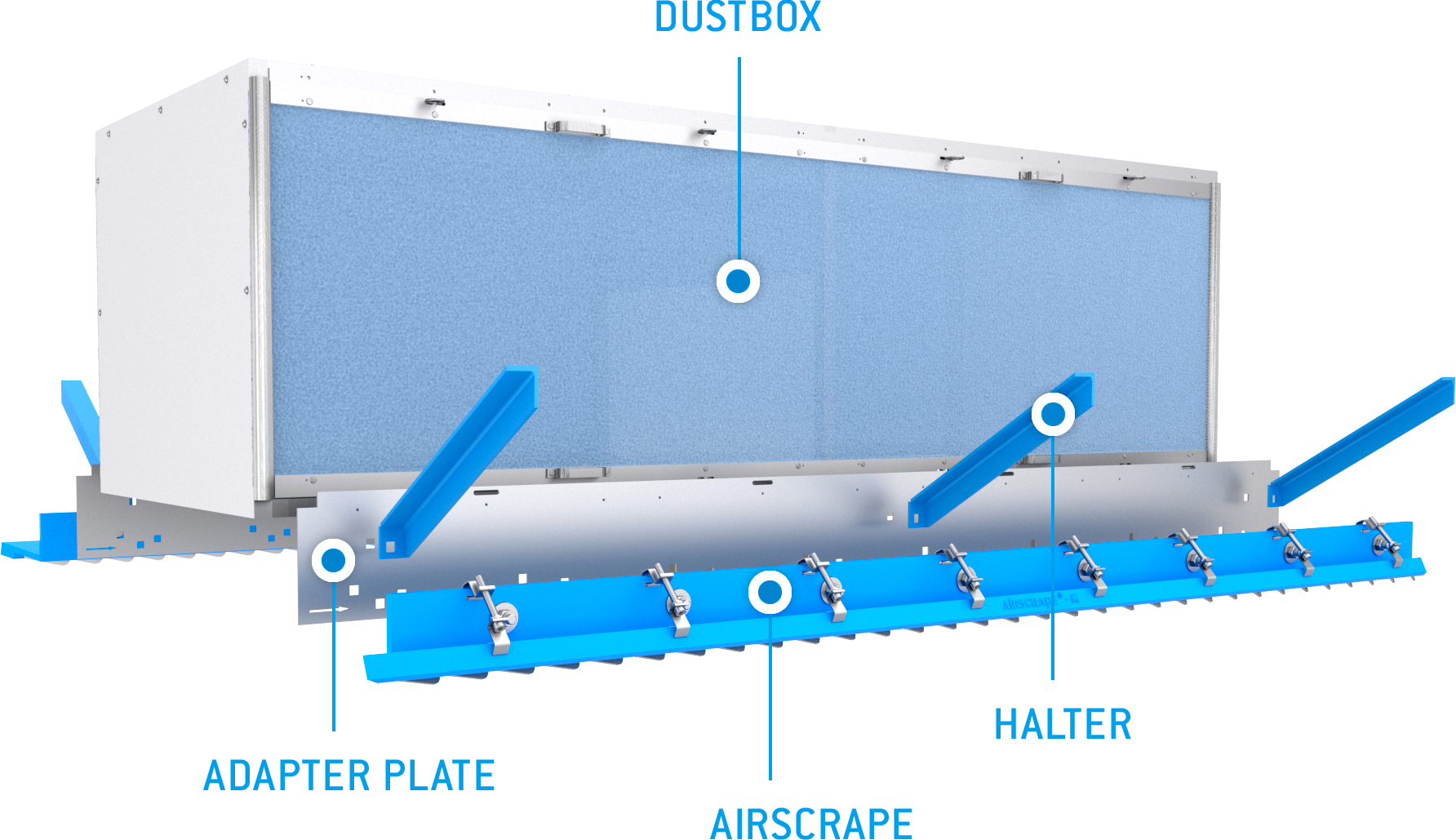

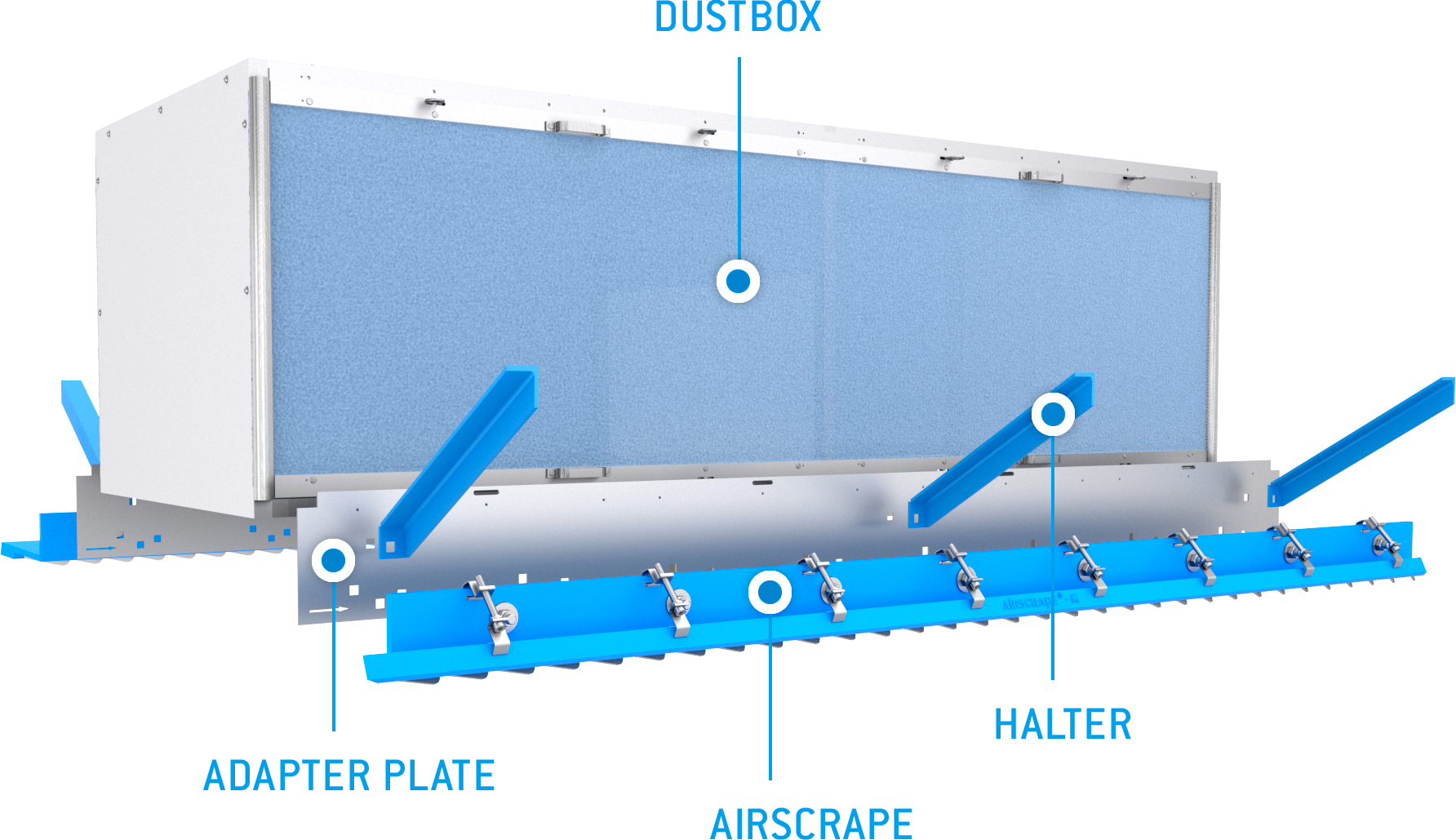

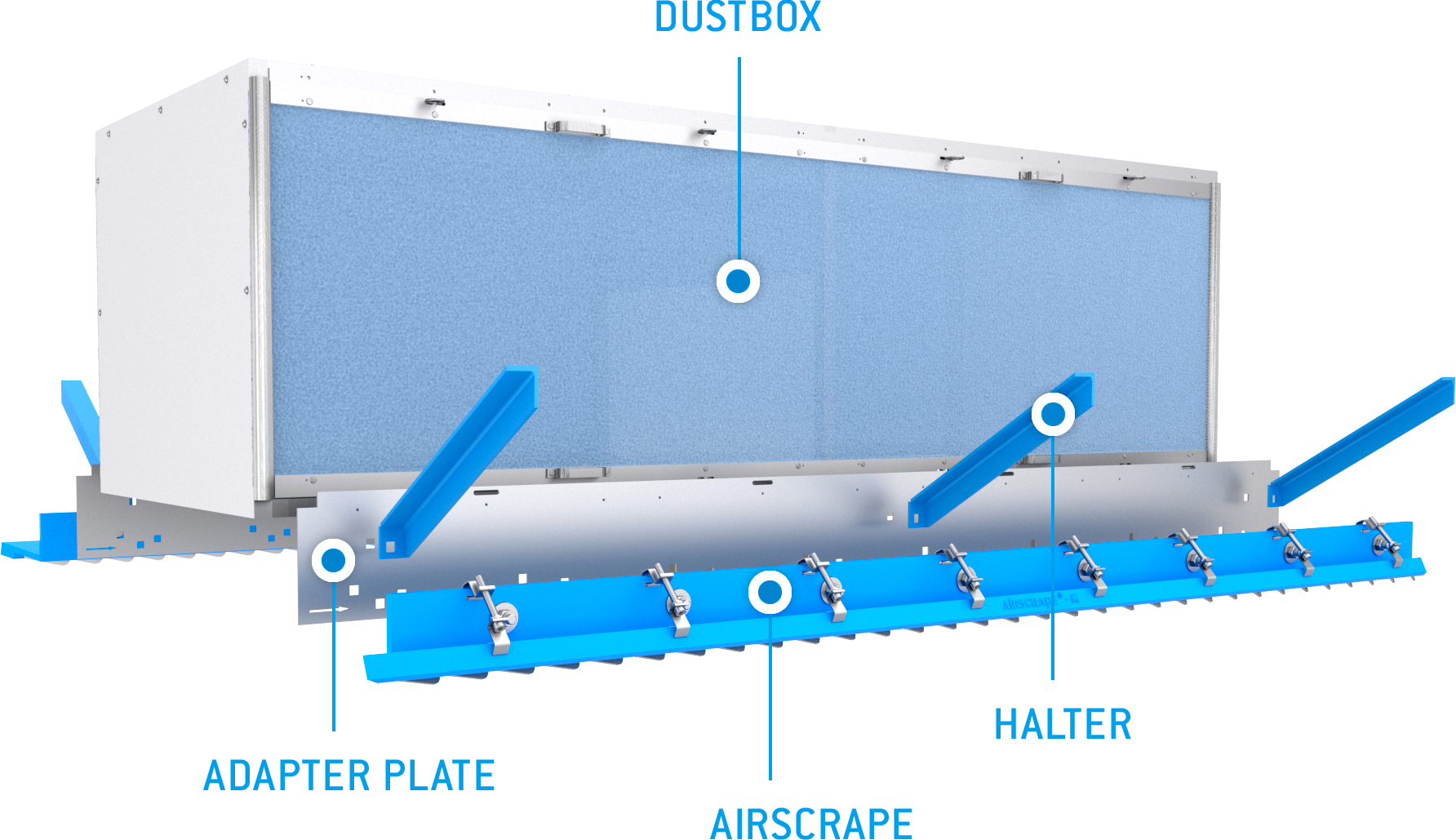

The DustBox

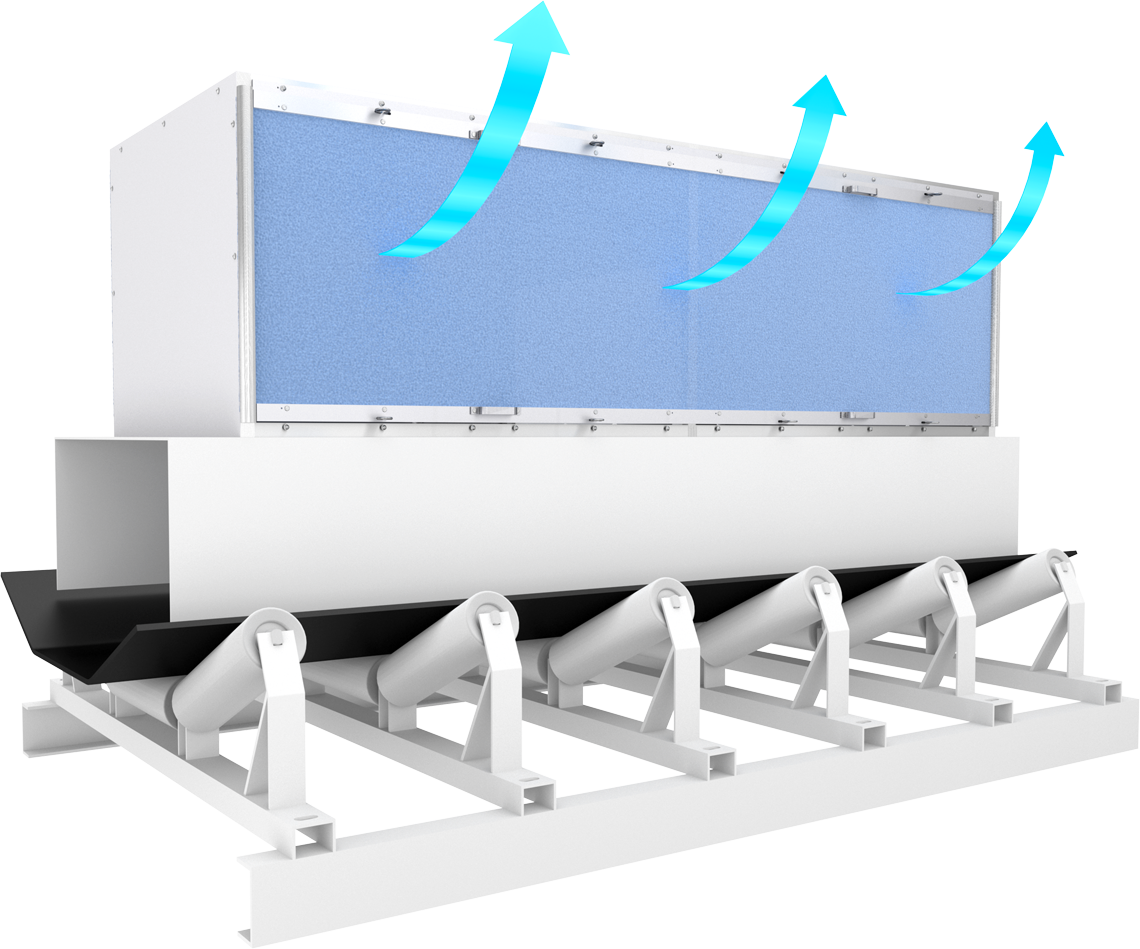

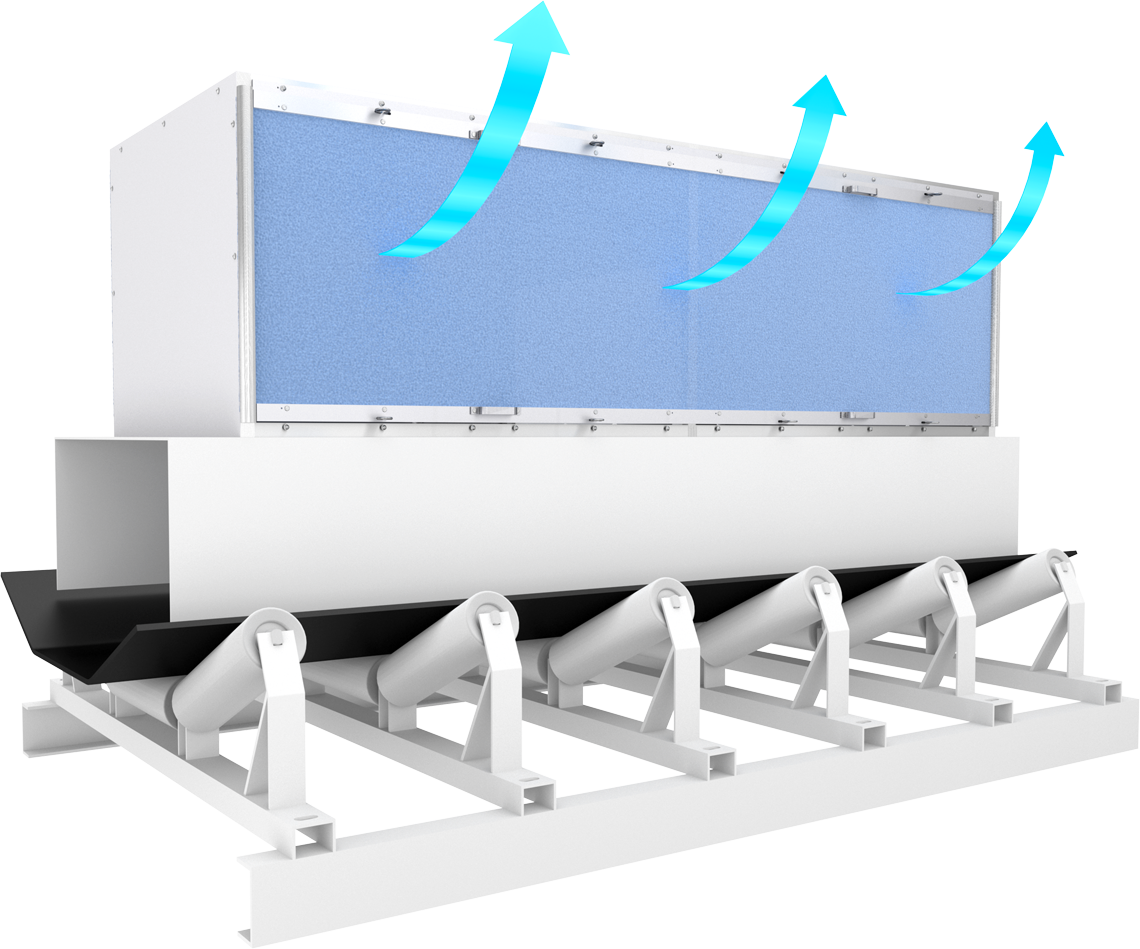

The filter cloth retains dust particles, generated by the falling process of the material in the conveying stream and at the same time is air-permeable for the resulting overpressure. The special antistatic filter cloth is designed for dust particles. The special selfcleaning property of the antistatic filtercloth enables dust to be retained for a very long time. Dust Dirt Scraper is also effective against drift and can be supplied in different filter cloth qualities, depending on the environment, also in stainless steel.

The DustBox

The filter cloth retains dust particles, generated by the falling process of the material in the conveying stream and at the same time is air-permeable for the resulting overpressure. The special antistatic filter cloth is designed for dust particles. The special selfcleaning property of the antistatic filtercloth enables dust to be retained for a very long time. DustScrape is also effective against drift and can be supplied in different filter cloth qualities, depending on the environment, also in stainless steel.

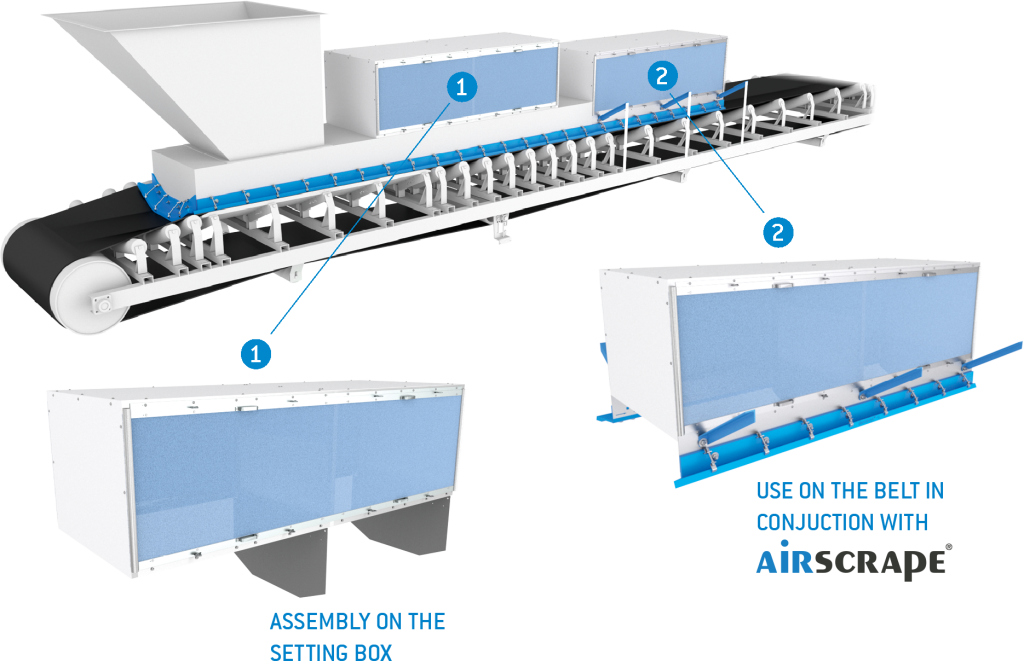

The Dust Box + Sidewall Seal + AirScrape = DustScrape

The dust box is easy to install, durable, maintenance-free and contactfree, and can also be combined with existing dust filtration systems. The combination of DustBox and AirScrape, the patented sidewall seal (not included), makes the „DustScrape“ a highly effective dust removal system against dust generation and thus helps to improving occupational safety and environmental protection. A highly efficient compact solution for operation dust-free conveyor belts at comparatively low cost and without the energy input of dust.

DustBox + Sidewall Seal + AirScrape = DustScrape

DustBox is easy to install, durable, maintenance-free and contactfree, and can also be combined with existing dust collection systems. The combination of DustBox and AirScrape, the patented sidewall seal (not included), makes the „DustScrape“ a highly effective system against dust generation and thus helps to improving occupational safety and environmental protection. A highly efficient compact solution for operation dust-free conveyor belts at comparatively low cost and without the energy input of dust.

AirScrape® ideally complemented

Dust Dirt Scraper is easy to install, durable, maintenance-free and contactfree, and can also be combined with existing dust collection systems. The combination of the Dust Box and AirScrape, the patented sidewall seal (not included), makes the „DustScrape“ a highly effective dust removal system against dust generation and thus helps to improving occupational safety and environmental protection. A highly efficient compact solution for operation dust-fr1ee conveyor belts at comparatively low cost and without the energy input of dust.

Advantages

- health protection through Dust Prevention

- easy retrofitting of existing systems, for improved compliance with the new dust guidelines

- suitable for any conveyor belt width

- easy installation

- maintenance-free and contactless

- available in different qualities

- extremely long-lasting dust retention due to selfcleaning properties of the SPECIAL filter cloth

- effective against dust up-drift

- reduction of energy costs

No energy required for dust extraction. If an existing dust extraction system is in operation, energy requirements will be reduced. - a contribution to occupational safety and environmental protection

- Only effective with the AirScrape® skirting (not included)

AirScrape® ideally complemented

DustScrape is easy to install, durable, maintenance-free and contactfree, and can also be combined with existing dust collection systems. The combination of DustBox and AirScrape, the patented sidewall seal (not included), makes the „DustScrape“ a highly effective dust removal system against dust generation and thus helps to improving occupational safety and environmental protection. A highly efficient compact solution for operation dust-free conveyor belts at comparatively low cost and without the energy input of dust.

Advantages

- health protection through Dust Prevention

- easy retrofi tting of existing systems, for improved compliance with the new dust guidelines

- suitable for any conveyor belt width

- easy installation

- maintenance-free and contactless

- available in different qualities

- extremely long-lasting dust retention due to selfcleaning properties of the SPECIAL filter cloth

- effective against dust up-drift

- reduction of energy costs

No energy required for dust extraction. If an existing dust extraction system is in operation, energy requirements will be reduced. - a contribution to occupational safety and environmental protection

- Only effective with the AirScrape® skirting (not included)