Fulminant start for ScrapeTec at bauma 2025 in Munich. Time for an short review befor entering the last part.

News

ScrapeTec Sets New Standards in the Grain Industrie

At this year’s GEAPS Exchange 2025 in Kansas, one topic in particular took centre stage. High dust levels and the associated risk of explosion. Conveyor system operators must optimise their systems in order to minimise safety risks.

Preserving Quality in Grain and Food Conveying

The use of unsuitable grain processing equipment can damage the grains. AirScrape reduces and prevents abrasion on conveyor belts and thus ensures that no microplastics and rubber get into the food.

ScrapeTec at bauma Conexpo India 2024

Among the visitors to the ScrapeTec stand were leading Indian companies such as Arcelor Mittal and Reliance, which are among the heavyweights of the steel and energy industry. ScrapeTec sees great potential in the Indian market for future cooperation and long-term partnerships in the field of steel and power plants as well as cement production.

AirScrape impresses at Bauma China 2024

ScrapeTec presented together with their long-standing china representative, Qingdao Best Friend Rubber & Plastic Co. Ltd, their innovative solutions on the bauma China 2024.

SOIDS 2024 – DustScrape at the top

ScrapeTec presented the new DustScrape with impressive innovations at SOLIDS 2024.

Networking at MINEXPO 2024

MSHA – 7 Good Reasons For The AirScrape

The AirScrape system is an important solution to consider in light of the new MSHA silica rules, which are set to take effect on June 17, 2024. Here’s why you should consider implementing AirScrape in your mining operations.

PrimeTracker: The Revolution in Conveyor Belt Technology

Traditional bottom belt trackers use mechanical resistance to guide the belt back to the center. However, this causes wear and requires regular maintenance. In contrast, ScrapeTec’s PrimeTracker controls the belt in an innovative way.

Effective Dust Control In Mining

BLT WORLD specialists work in conjunction with the global ScrapeTec team to offer dependable solutions for specific problems at the transfer points of conveyor systems in many industries where dust and material spillage are concerns, including in mining and quarrying.

Exponor Chile Antofagasta 2024 Report

This year marked the second participation for Scrapetec alongside our partner Dank Consultores. Our new patented dust control technology aroused great interest.

MSHA Silica Rules – Solutions from ScrapeTec

In the mining industry, ensuring compliance with health and safety regulations is paramount to protect workers from potential hazards. One such regulation that has garnered significant attention is the Mine Safety and Health Administration (MSHA) Silica Rule.

Solutions in materials handling technology

Based on more than 3 decades of know-how in the area of materials handling technology, we have been analyzing critical points in conveyor systems and developing new cost-efficient solutions for improvement and optimization.

Effective dust control in leading copper mine in Peru

A leading copper mine in Moquegua Province in Southern Peru – has made an investment in ScrapeTec’s highly-effective dust suppression and material spill solutions, that are setting a new trend in conveyor systems used in the global mining sector.

SCRAPETEC’S DUST AVENGER

In the dusty world of industrial mines, workers battled daily against a brutal and visible enemy: dust. It was everywhere, on machines, in the air, and on their skin. It made work not just unpleasant, but dangerous, as dust can lead to serious health issues.

ScrapeTec and Wangoo at the MAWEV SHOW in St. Pölten

Networking hub and knowledge exchange: The MAWEV SHOW in St. Pölten, Austria is a leading trade fair for construction for construction machinery, construction equipment and construction vehicles. It gives industry experts the chance to explore the latest technologies. An important platform for knowledge transfer.

2024 IEEE-IAS/PCA Cement Conference with Scrapetec on board!

GEAPS Exchange 2024 Show for the first time!

The GEAPS Exchange 2024 in Kansas City MO was the global center for grain handling this year. This prestigious trade fair, the largest of its kind worldwide, was attended by approximately 3 700 visitors and 1 000 companies from about 23 countries.

Scrapetec at the GEAPS Exchange in Kansas City

The renowned GEAPS Exchange trade show in Kansas City is once again opening its doors to enthusiasts and professionals from around the world. This year, ScrapeTec will be presenting its innovative products for the first time at this trade fair together with BLT World from South Africa.

Highlights at the Global Gypsum Conference 2023 in Chicago

Dust prevention solutions for conveyor belt transfers at the Global Gypsum Conference in Chicago. ScrapeTec met the challenge of saving energy and maintenance costs with positive feedback.

ScrapeTec & Kinder at the Perth fair

ScrapeTec sponsert Team Speculum – Shitbox Rally, Spring 2023

In seven days, more than 500 teams drive 3,200 km across Australia and collect donations for cancer research. We support our partner and friend Charles from Kinder Australia Pty Ltd. in this great campaign, his team SPECULUM has already raised $9,200 through donations for the good cause.

15. Global Slag Conference

ScrapeTec presents ten individual project solutions for seamless and hassle-free material transfer at the 15th Global Slag Conference in Düsseldorf.

Simply Switched Off Excessive Dust And Spillage

Due to high material drop at the transfer chute an excessive amount of dust and spillage was observed. Faced with the ongoing dust and spillage predicament, the Maintenance Supervisor specifically sought a low maintenance, long lasting solution to suppress and minimise the excess dust/spillage at the facilities outdated tail end transfer chutes.

Unique power saving dust protection

Even before the trade fair, the topic of saving electricity through dust protection solutions from ScrapeTec was already a subject of discussion. The focus was on the DustScrape in combination with the AirScrape. Also at SOLIDS 2023, to be experienced live.

0% Dust Emission, 0% Energy Costs

At many trade shows and during visits to customer facilities, the ScrapeTec team learns a lot about the immense energy costs associated with dust extraction on conveyor systems. These fixed costs are often cited as an argument against investing in innovations for dust protection.

Potential and prospects

ScrapeTec had interesting encounters at this year’s Mining Indaba in Cape Town, the major African trade fair for mining. The tenor: Solutions are being sought to minimize the costs of dust generation and spillage.

New projects in Australia

In 2017, the AirScrape was presented for the first time at the leading trade fair AIMEX in Australia. In the meantime, many mining companies Down Under have been won over by the innovative side seal for handovers. Also in the cement industry.

Ready for Remote: The new E-PrimeTracker 4.0!

Visitors to the ScrapeTec Trading GmbH stand at this year’s bauma were able to see all the products from the dust protection specialist for conveyor systems in action on a special test belt system.

Mumbai is calling

In addition to Europe, USA, Peru, Chile and Australia, India is now another important milestone for the Kamp-Lintforter. Now another order came from India.

Bom dia Brasil

The great land of Brazil has many mineral resources and corresponding mining capacities. Managers from big mines and cement plants around the Sugar Loaf have already asked ScrapeTec. As always, the AirScrape, the contactless skirting, is the focus of many interested parties. Same in Brazil.

First-hand information on innovations

AirScrape on everyone’s lips. And in everyone’s hands.

Sales partner Dank experiences a run at its booth at EXPONOR 2022 in Chile.

ScrapeTec at the Underhall fair in Gothenburg

At this year’s UNDERHALL trade fair in Gothenburg/Sweden, we presented our product range together with our Swedish sales partner Rubber Company AB.

The Essential AIR SEAL – Dust Containment Combination

A cement production operator based in the Port of Brisbane needed to deal urgently with excessive dust emissions, material spillage and other problems on the transfer point. Dust and spillage levels were high and constant during ship unloading process.

BEUMER Group discovers ScrapeTec innovations

ScrapeTec presents his sustainable solutions for all aspects of the transfer point on December 1st at BEUMER HQ in Beckum.

Mining Technology Of The Future – Expomin 2021

ScrapeTec Partner Dank Consultores is presenting the AirScrape at Expomin, the most important trade fair for mining in Chile in Hall 2, Stand J-56 on October 27. – 29. 2021.

A New-State-Of-The-Art Conveyor Skirting

An added advantage for industry is to be able to cope efficiently with the challenges of moist and sticky materials. The ScrapeTec team has developed advanced solutions for handling of difficult bulk materials.

Proud To Be Aboard

ScrapeTec GmbH is now on Codelco’s supplier list and sends first AirScrape conveyor skirtings to the mine in Chuquicamata.

Efficiency at its Best

Dust-, spillage- and maintenance-free Skirtings supplied from Kamp-Lintfort, Germany conquer the World of Mining.

INNOVATIVE SOLUTIONS

for the efficient control of dust and material spills in underground conveyor hanling systems.

New AirScrape article published on the Mining Innovations Africa Website.

PrimeTracker launched in South Africa

BLT WORLD’s launches the new Scrapetec Primetracker conveyor belt tracker on the South African market.

Busting The Dust – BMHR 2020

Most of the classic dust prevention methods involve risks and side effects such as increased wear and tear, causing plant operators to face different problems. AirScrape the new conveyor skirting from ScrapeTec Trading GmbH keeps fine dust particles in the conveying area, eliably preventing spillage and – since it works without belt contact – significantly reduces the need for maintenance work.

New sales partner in the Spanish market

We could win an excellent sales partner with the Spanish MASANÉS SERVINDUSTRIA Group. From now on our products are also represented in the Spanish market and already used in existing projects…

COSENTINO tested the AirScrape with a positive result

The Spanish COSENTINO Group tested the AirScrape with a positive result and decided to convert further transfers in the production chain.

BLT SOUTH AFRICA is our new distributor in South Africa

We are expanding our distribution network and have signed an agreement with BLT SOUTH AFRICA for the distribution of our products in the South African market.

Belt conveyors and their components

In the scope of the 14th conference in the “Haus der Technik“ in Essen, the engineer Wilfried Dünnwald (Dipl. Ing.) will present efficient methods of optimization at transfer points…

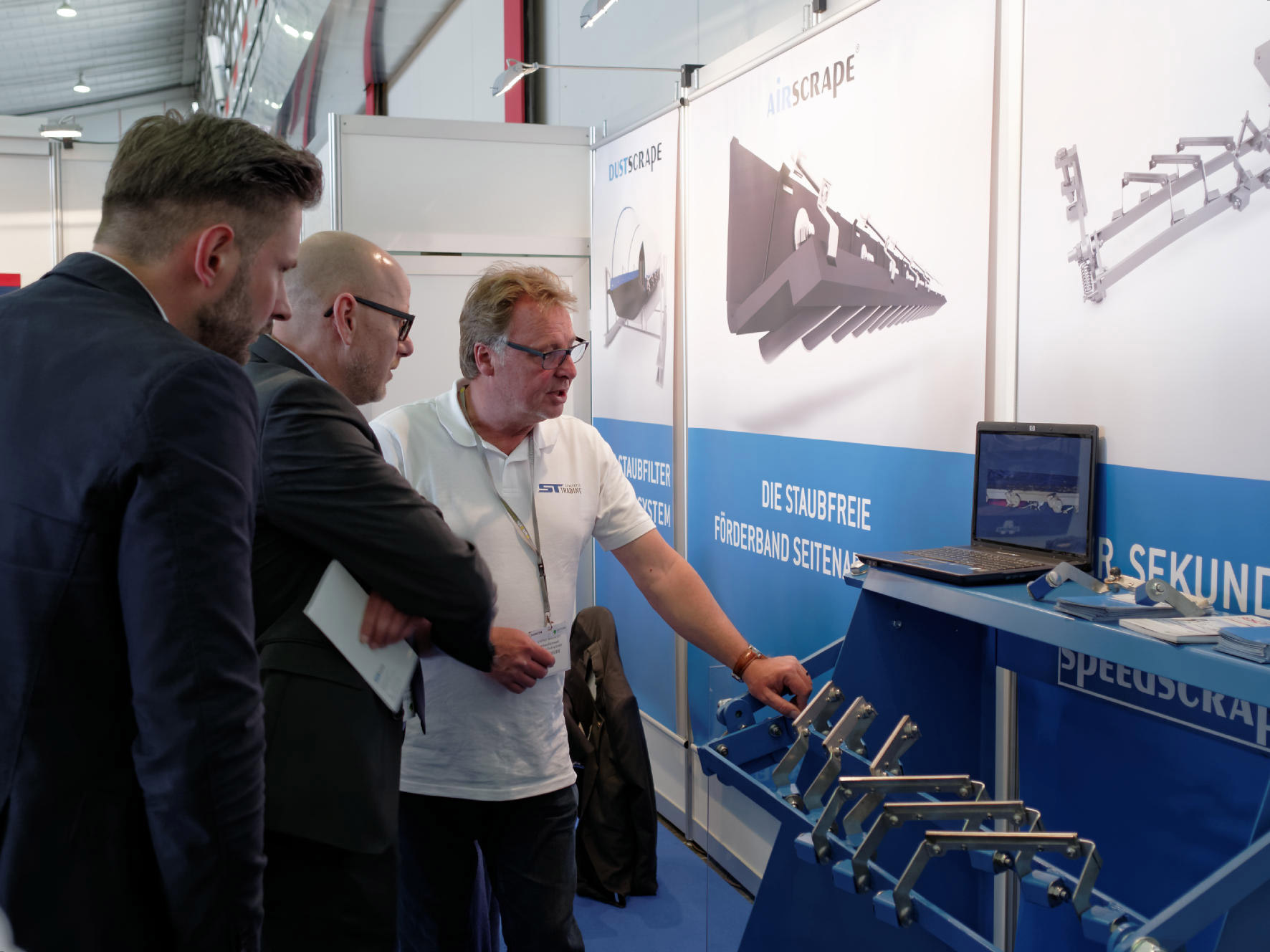

Introduction of the new SpeedScrape at the exhibition

At the “Schüttgut 2017“ (Bulk Material 2017), we introduced the new SpeedScrape for the first time. The new technology attracted a lot of attention among the expert audience…

Everything under control

The Rump & Salzmann Gipswerk Uehrde GmbH & Co KG, had regularly occurring problems with dust and loss of material at the transfer point from the rotor crusher to the belt…

Introduction of the DustScrape to the Australian market

At the AIMEX in Sydney, Australia, we introduced the DustScrape to the Australian market and presented a new and innovative solution to avoid dust and material spill…