Ready for Remote:

The new E-PrimeTracker 4.0!

bauma 2022 has opened its doors and the global trade audience came to Munich to discover innovations. Also present: The E-PrimeTracker from ScrapeTec, the new generation of the “conveyor belt tracker” PrimeTracker. Equipped with additional sensors, it works remotely and sends its data on the belt status to the monitoring systems. In the spirit of condition monitoring, predictive maintenance and Industry 4.0.

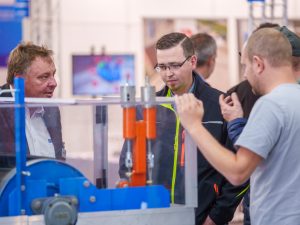

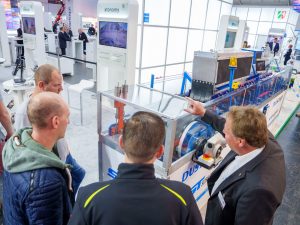

Visitors to the ScrapeTec Trading GmbH stand at this year’s bauma were able to see all the products from the dust protection specialist for conveyor systems in action on a special test belt system: In addition to the legendary AirScrape conveyor transfer point skirting that works without contact, the TailScrape rear seal that works on the same principle, the dust protection settling area DustScrape and the belt SureSupport, the E-PrimeTracker could now also be seen for the first time. Installed at the returning belt, where it monitors and corrects misalignement like the analogue version PrimeTracker. The special difference: The E-PrimeTracker is equipped with sensors that record the status of the special guide roller and thus also the status of the belt run. On the one hand, the trade visitors could see that the recorded condition can be read directly on the device via a light display. The color fields in green and red light up according to the situation. Green indicates that the belt is running optimally, red indicates that faults in belt synchronism that cannot be corrected have been detected. The red warning signal indicates that inspection is necessary in order to avoid possible belt damage or even a unscheduled breakdown. On the other hand, the data from the sensors are also transmitted remotely. Either wirelessly to a monitoring system that is already in use in the plant or, as ScrapeTec is currently developing: to the app. A prototype of the app was also presented at the booth to make the monitoring features clear.

Many company representatives at the booth showed great interest in using the E-PrimeTracker in one of their plants. That would be a win-win situation: ScrapeTec can then demonstrate the practicability of the E-PrimeTracker during operation and the plant operators can use the advantages of the condition monitoring of their plants. For example, the timely detection of critical events and operating states with a high potential for wear and tear. Special situation and resulting errors can be classified and evaluated through monitoring. This enables timely and targeted intervention. The critical events already mentioned or undesired operating states can be eliminated immediately through quick reactions. This corresponds entirely to the idea of ”predictive maintenance” to avoid costly consequential damage. This includes downtime. In this way, they are significantly reduced, since service technicians, spare parts and logistics can be made available in a targeted manner. It is not for nothing that ScrapeTec chose the suffix 4.0 for its innovation E-PrimeTracker. The remote capability and the integration into a condition monitoring system follow the orientation of Industry 4.0. In addition to the digitization of the processes, “machine learning” is also being promoted, with which the effectiveness of the systems can be optimized in the long term.

With the sensory equipment and the monitoring suitability, ScrapeTec serves exactly this change, which is also noticeable in the area of conveyor systems for bulk goods. Even if ScrapeTec Trading GmbH was part of a joint stand for the mining competence of the state of North Rhine-Westphalia at bauma, the advantages of the solutions for dust protection are recognized across all sectors. They concern conveyor systems for any material. And with the presented E-PrimeTracker, the company around developer Wilfried Dünnwald has once again proven its innovative strength. Also for the future. Because the app belonging to the E-PrimeTracker, to allow mobile monitoring, was presented at the bauma as a prototype in the example system of the stand. The final market launch will follow soon. The demand is high, which was also shown by the large number of visitors to the ScrapeTec stand.