AirScrape® is a conveyor belt skirting system developed, patented, and manufactured in Germany to meet the highest standards of quality, safety, and environmental protection. With its unique technological solution, it is the world’s first and only air skirting system for conveyor belt operations.

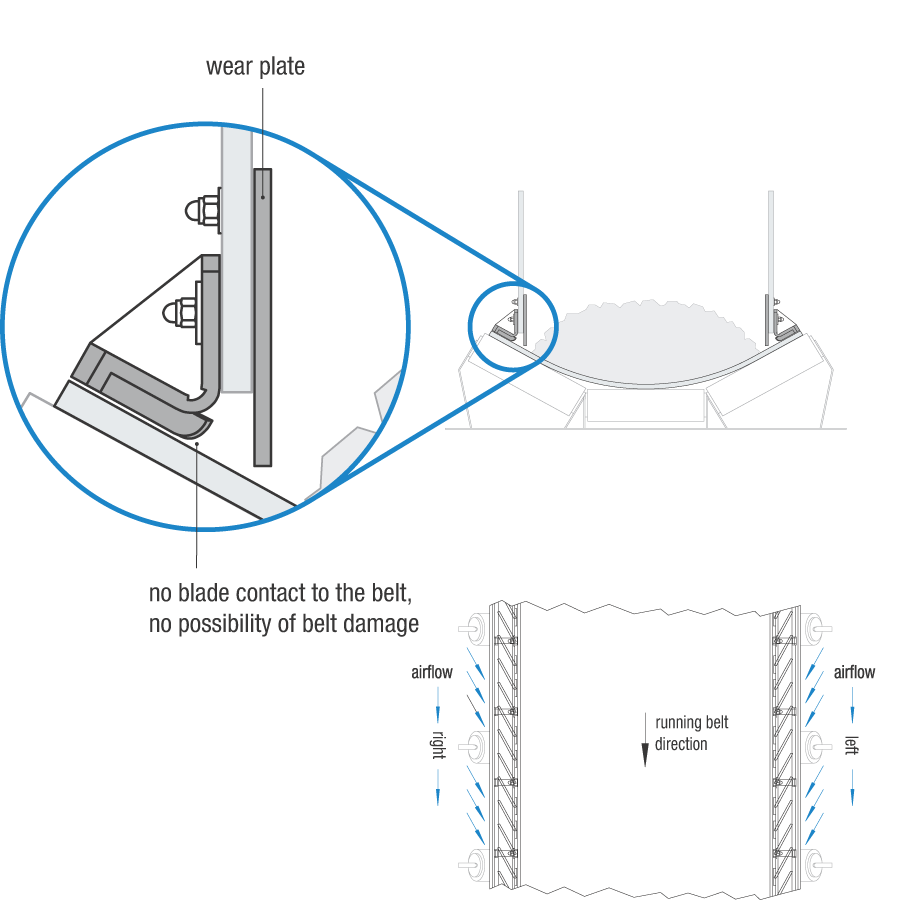

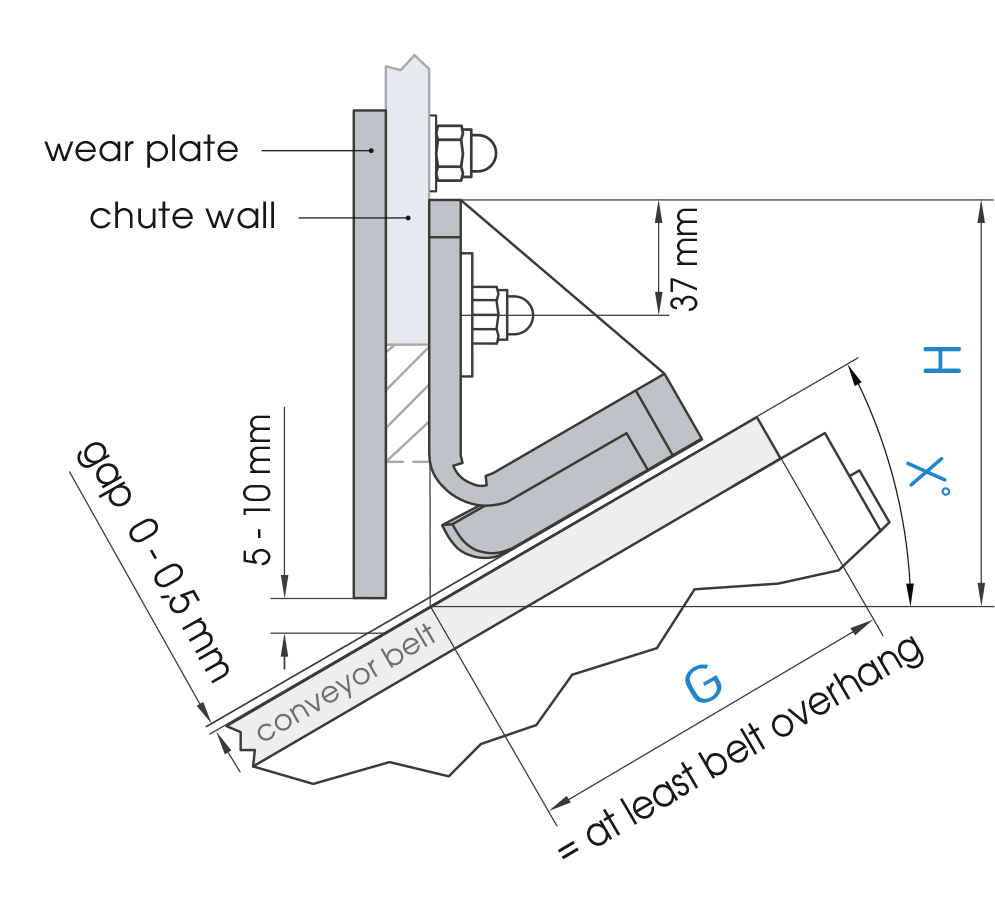

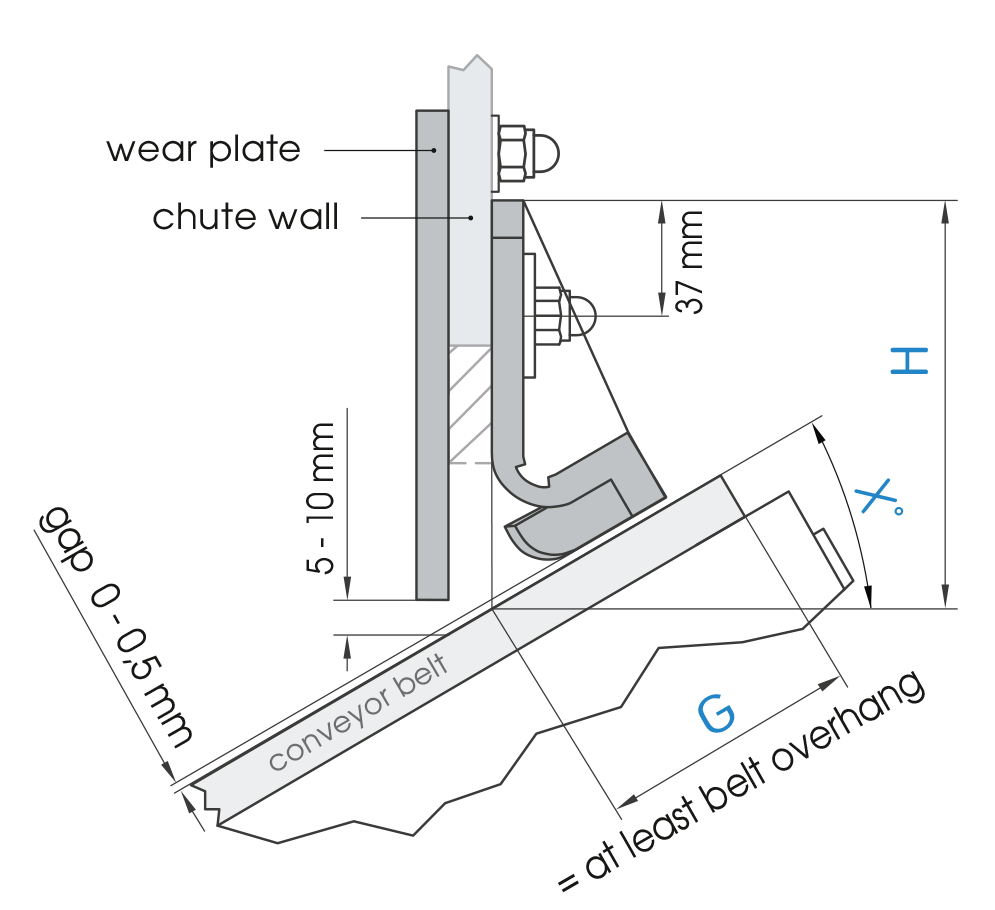

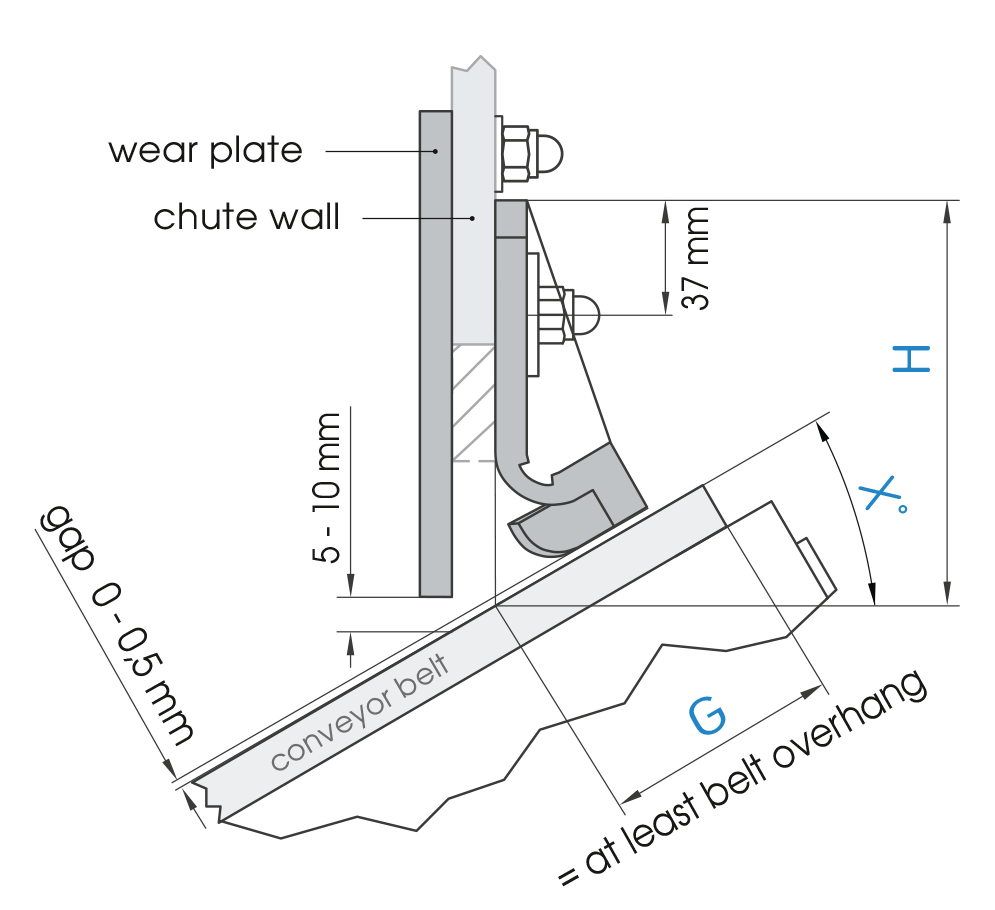

This contact-free Airscape conveyor belt skirting system acts as a highly effective side seal, suspended over the conveyor belts skirting. The innovative diagonal arrangement of hardened lamellae directs air from the outside into the middle of the belt, creating an air suction effect. This enhances dust containment, ensuring fine particles stay within the conveyor section. Additionally, coarse materials that push outward are redirected back to the middle of the belt, significantly decreasing spill and improving efficiency at conveyor transfer points.

The innovative AirScrape® design offers a triple positive effect. This Airscape conveyor belting solution minimizes dust formation and material spillage at transfer points and other critical conveyor sections. Because this belt skirting system hovers freely above the conveyor belt, it eliminates skirt friction and prevents belt damage, thereby extending the service life of every conveyor component.

In industries dealing with heavy material transfer or even specialized applications like scrap air conditioner recycling, AirScrape® delivers an unmatched solution for cleaner and more efficient conveyor operations.