Saving energy costs with DustScrape

The ScrapeTec energy-saving formula: Energy costs for dust removal minus DustScrape

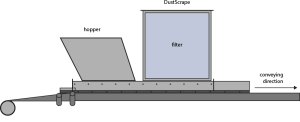

The ScrapeTec energy-saving formula: Energy costs for dust removal minus DustScrape The calculation is simple: By investing in a ScrapeTec dust protection solution around the DustScrape at the transfer points of a conveyor system, the entire energy costs of dust extraction can be saved – so they are reduced to zero. This is because the use of the filter module DustScrape and the innovative sealing solutions AirScrape and TailScrape allow the dust extraction to be turned off. The seals work contactlessly with special profiles and thus create the Venturi effect: the air is sucked inwards. Dust does not escape, and the bulk material also remains on the conveyor belt. The DustScrape, with its special and robust filter cloth, captures the dust that arises from the fall energy before transfer/feeding in the direction of the conveyor.

The interplay of these components has now proven itself worldwide wherever dust protection solutions have been sought. The argument for energy savings is relatively new and comes from specific customer experiences. The affected customer was convinced and highly motivated to equip other systems with DustScrape, AirScrape, and TailScrape after demonstrating the cost savings on a conveyor system through their own controlling. Regarding costs, the use of the ScrapeTec dust protection solution can also save cleaning, maintenance, and repair costs, as the solution is maintenance-free since the contactless seals operate without friction, do not wear out, and also leave the conveyor belt intact. And: downtime for cleaning is also eliminated. ScrapeTec has gained a lot of experience in presenting the advantages of using a dust protection solution around DustScrape to interested operators of systems individually. Cost savings are one of the most important arguments from a business perspective, especially in discussions with those responsible for accounting to shareholders.

-to be continued-