The conveyor belt is one of the most expensive components of belt conveyors. Poor belt guidance leads to excessive wear and inevitably to early replacement, resulting in high replacement costs and short service lives.

In the field of belt guidance, we have broken new ground and we have added a product to our portfolio that actually sets new standards.

Minimum wear – long service life

The new PrimeTracker works unlike conventional belt guidance systems. Due to its unique design, it acts like a standard conveyor belt roller when the belt runs smoothly and only intervenes when the belt leaves its optimum position. The PrimeTracker responds before the guide roller tilts horizontally. As soon as the conveyor belt runs off-centre, the Prime Tracker corrects the movement with small forces and very low friction, thus preventing unnecessary wear.

Minimum wear – long service life

The new PrimeTracker works unlike conventional belt guidance systems. Due to its unique design, it acts like a standard conveyor belt roller when the belt runs smoothly and only intervenes when the belt leaves its optimum position. The PrimeTracker responds before the guide roller tilts horizontally. As soon as the conveyor belt runs off-centre, the PrimeTracker corrects the movement with small forces and very low friction, thus preventing unnecessary wear.

Effect of the PrimeTracker in case of belt misalignement

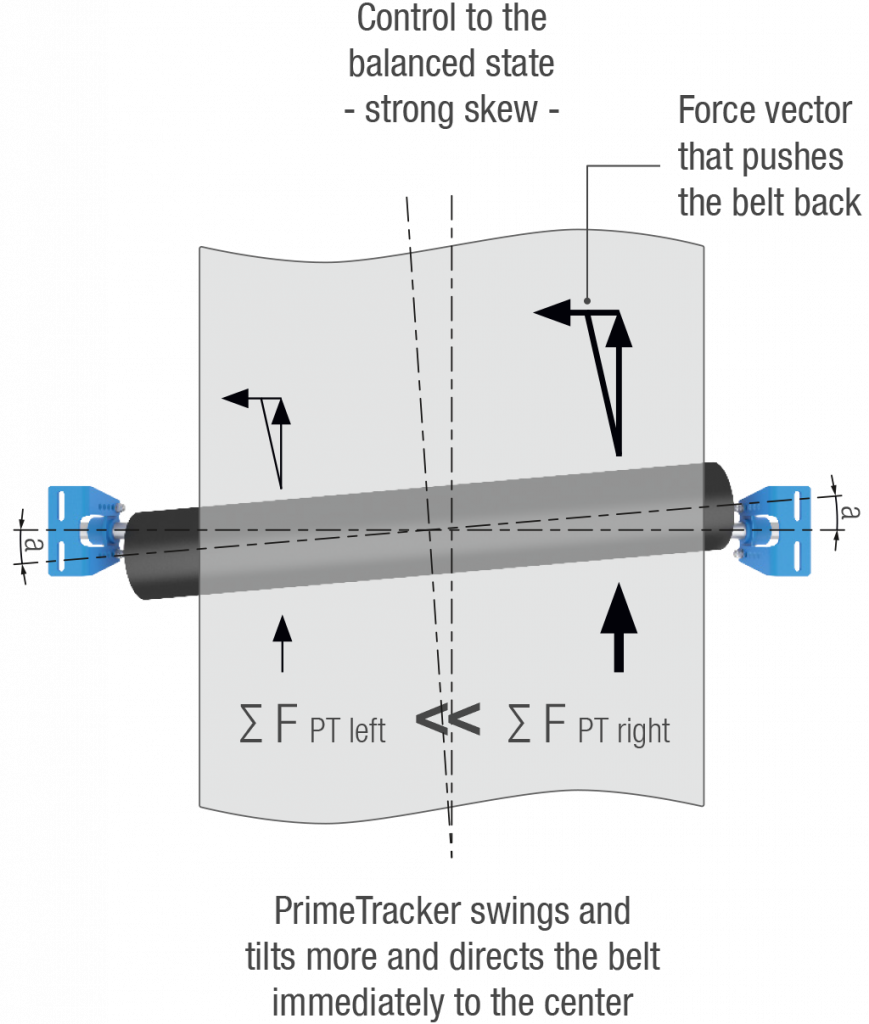

The specially developed maintenance-free mounting of the PrimeTracker allows a change of the rotating roller‘s axis position in all directions. The rubberized cylinder body can tilt and swing. With soft pressure, it provides continuous guidance over the complete contact surface. The PrimeTracker is physically designed to detect even the slightest deviation in the belt run from the optimum line and to react with the corresponding counterforce. The counterforce the PrimeTracker applies is determined by the extent to which the belt deviates from the optimum belt position. It is the first belt tracker of its kind and completely different to conventional belt trackers.

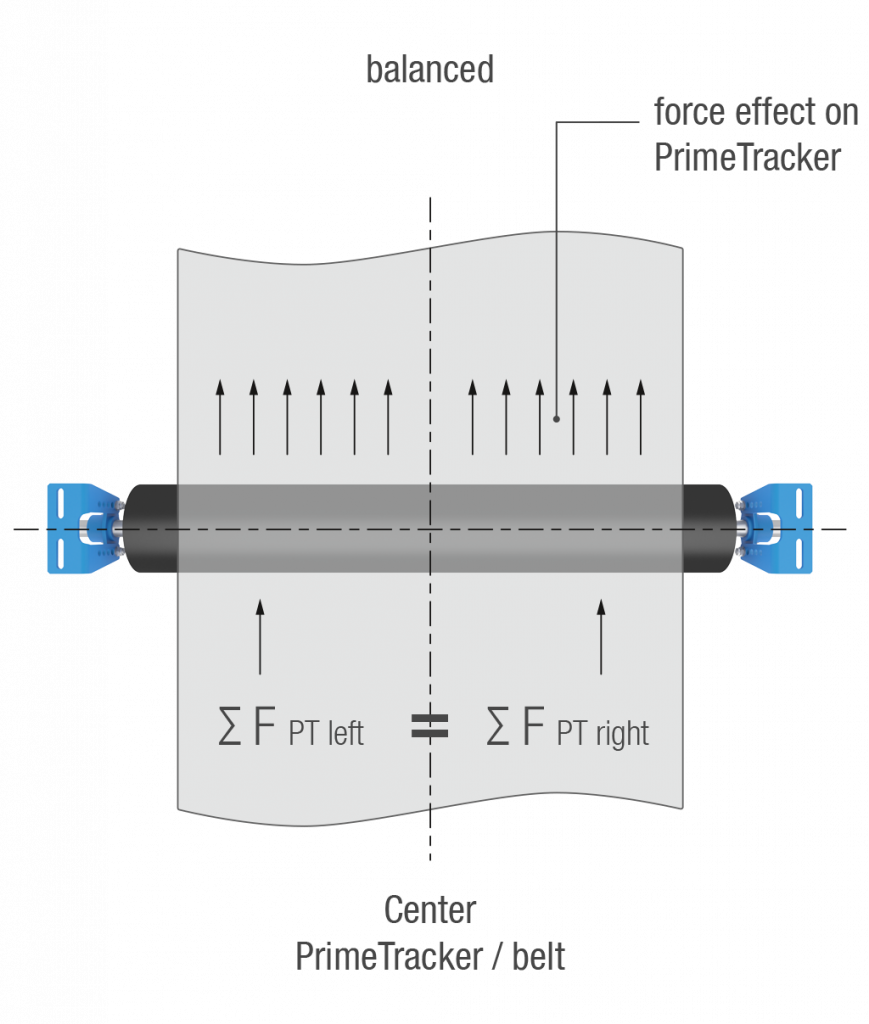

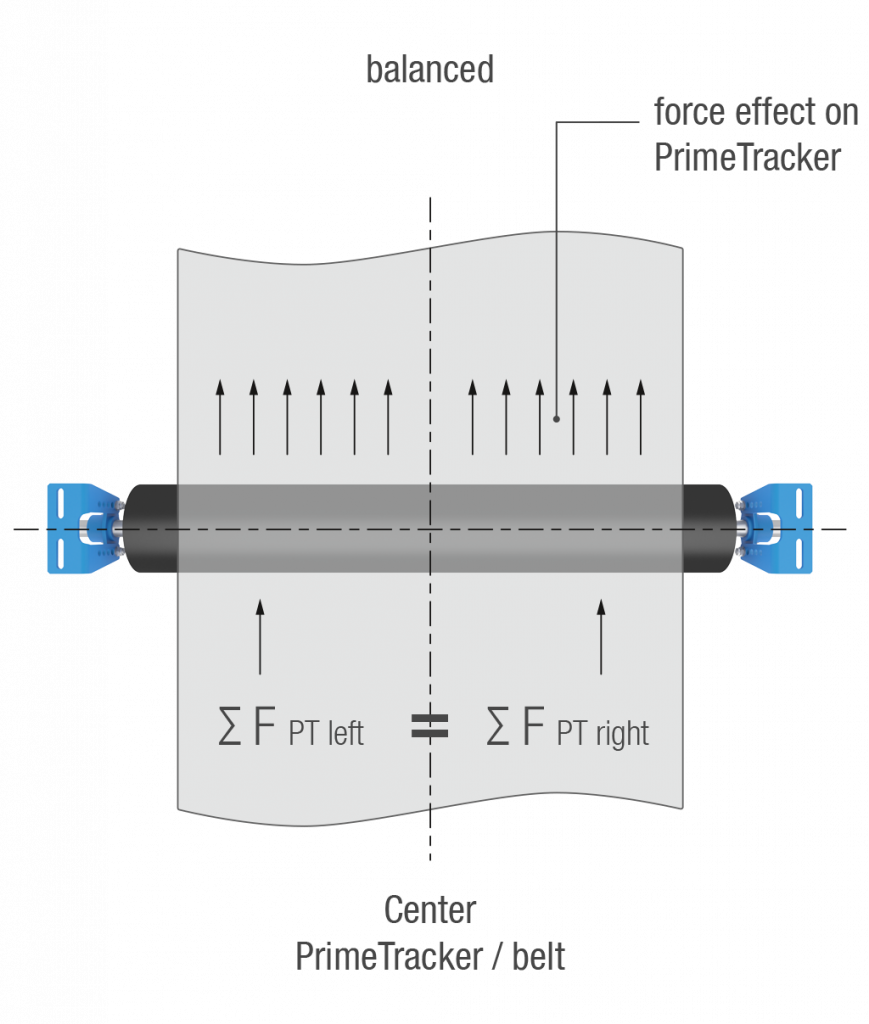

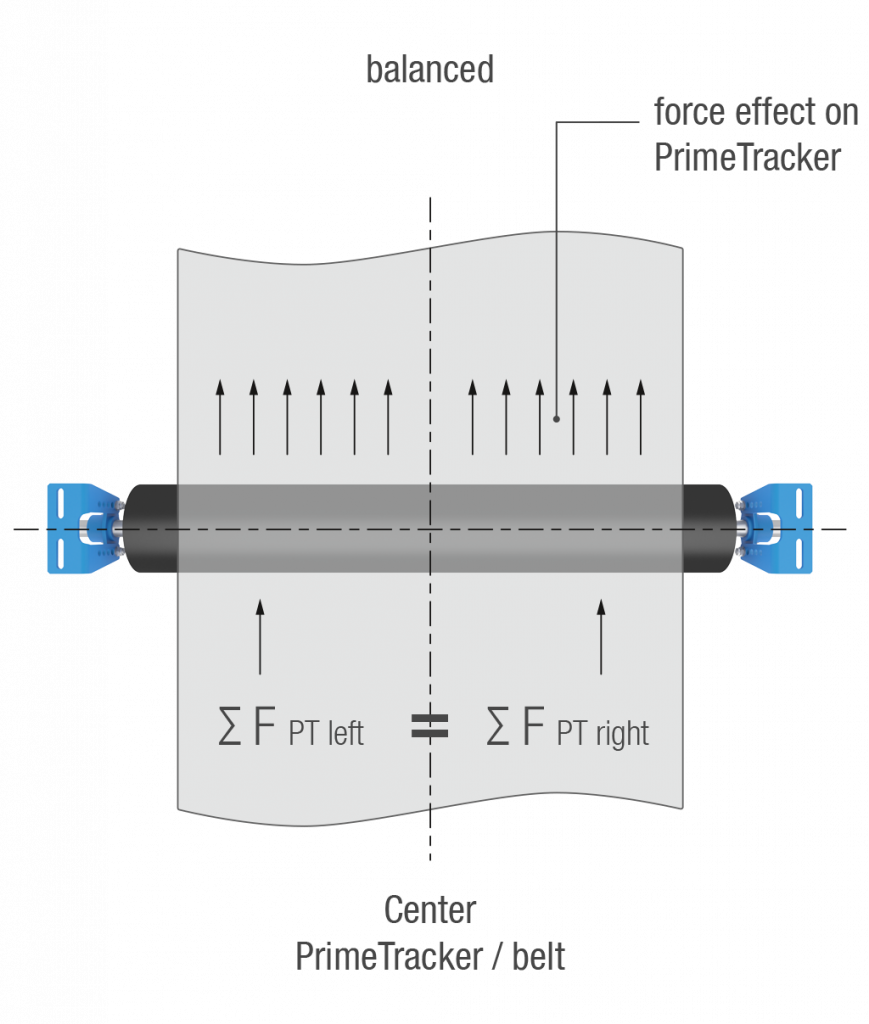

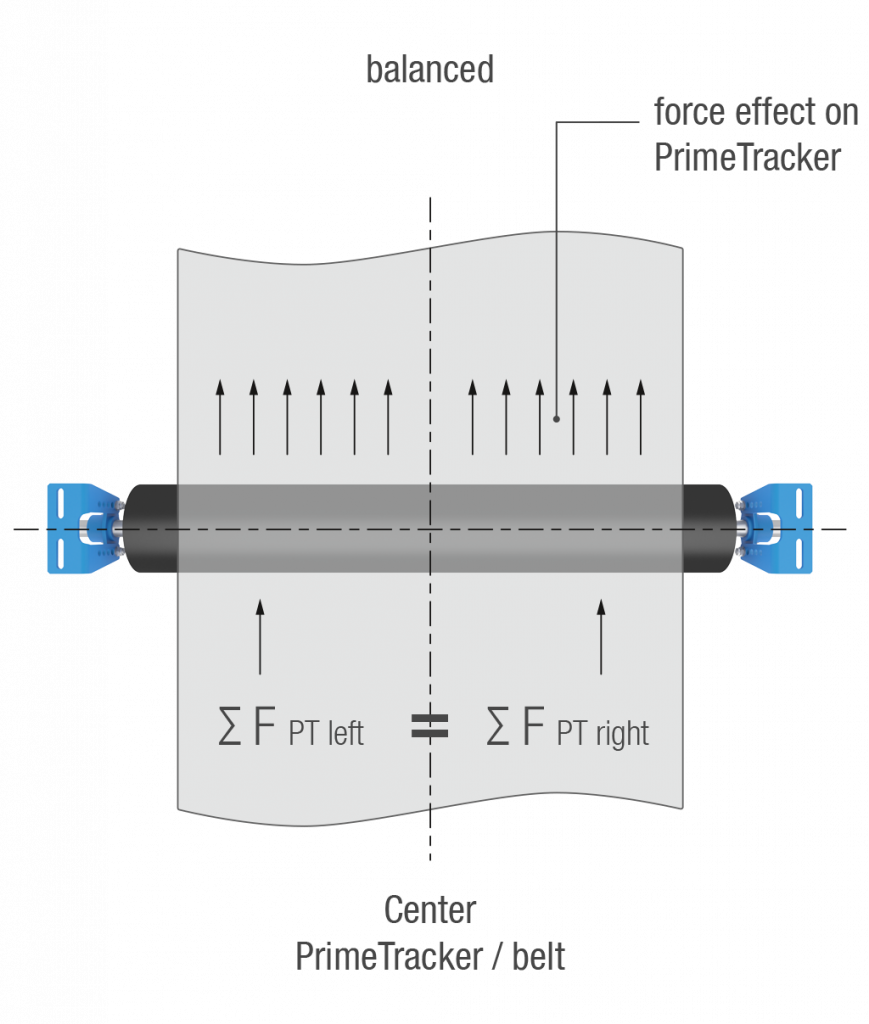

Balanced

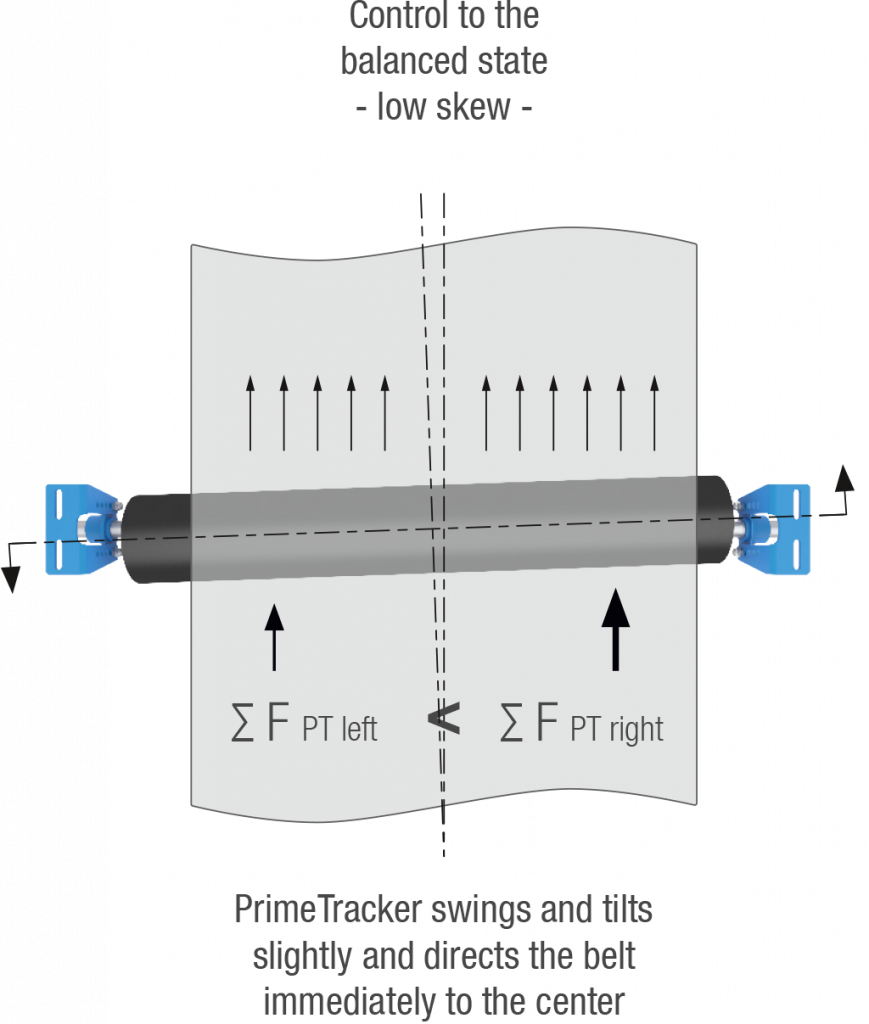

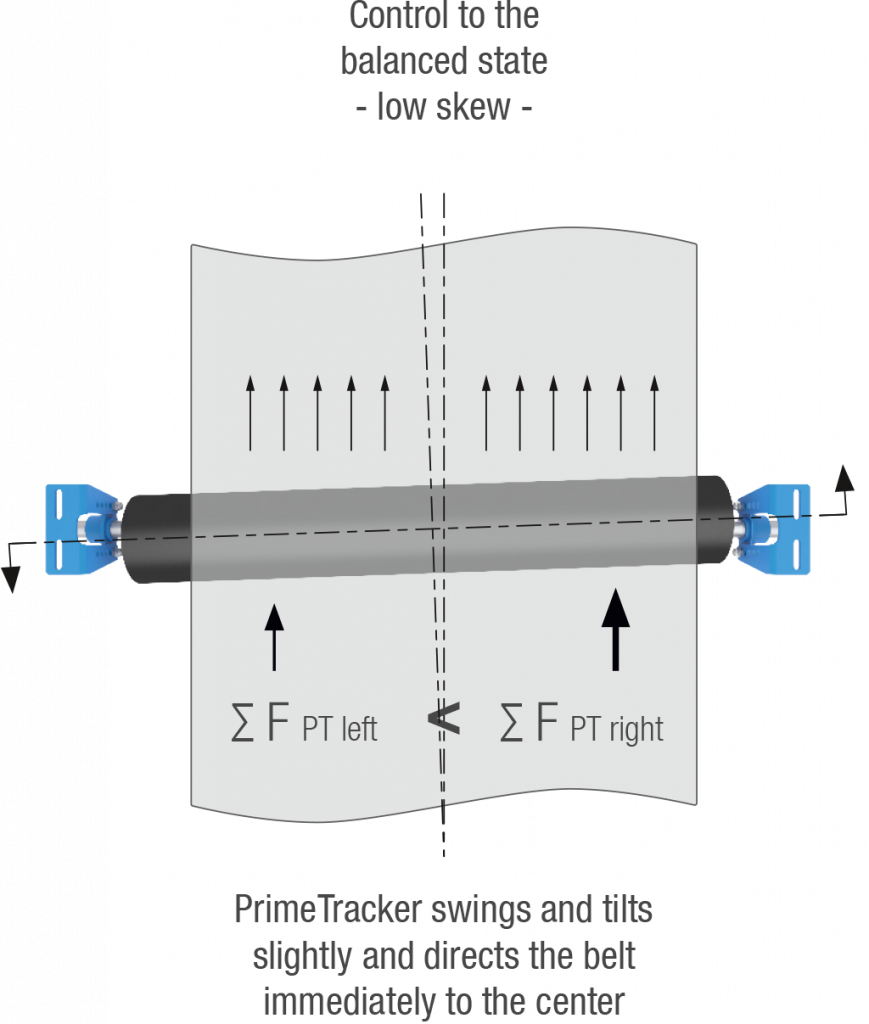

In case of slight misalignment

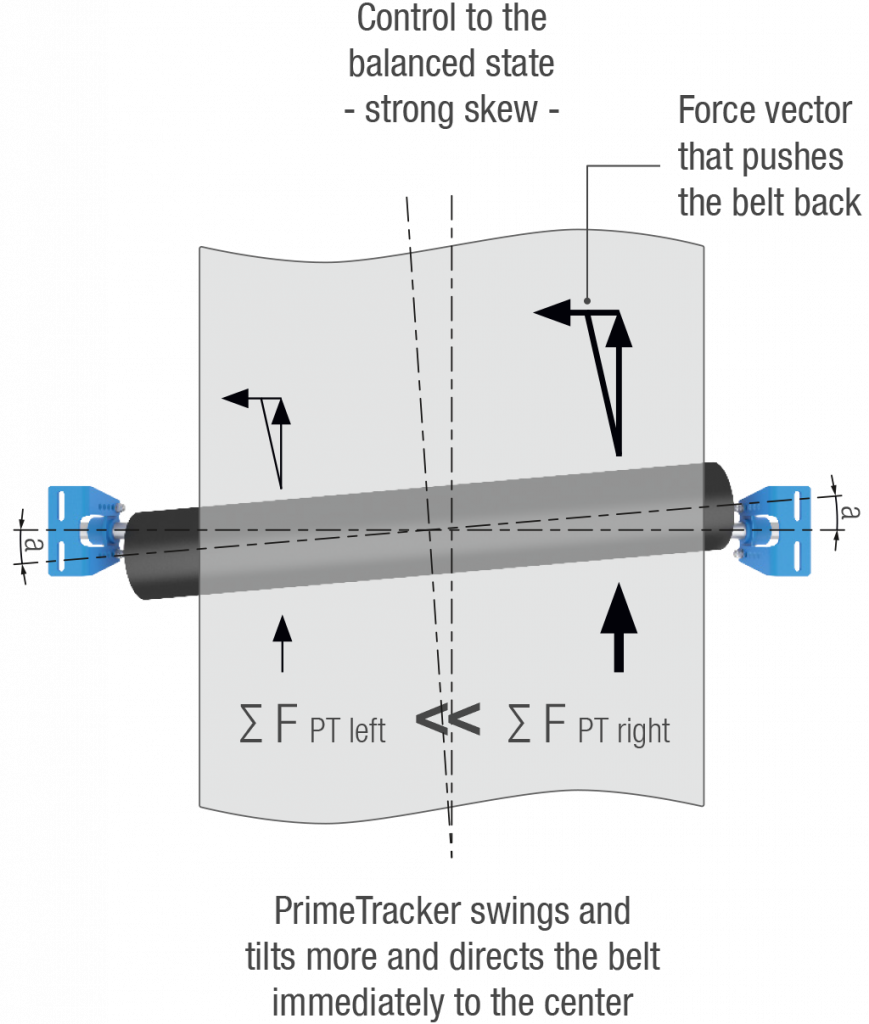

In case of strong misalignment

Balanced

Effect of the Prime Tracker in case of belt misalignement

The specially developed maintenance-free mounting of the PrimeTracker allows a change of the rotating roller‘s axis position in all directions. The rubberized cylinder body can tilt and swing. With soft pressure, it provides continuous guidance over the complete contact surface. The PrimeTracker is physically designed to detect even the slightest deviation in the belt run from the optimum line and to react with the corresponding counterforce. The counterforce the PrimeTracker applies is determined by the extent to which the belt deviates from the optimum belt position. It is the first belt tracker of its kind and completely different to conventional belt trackers.

Balanced

In case of slight misalignment

In case of strong misalignment

Balanced

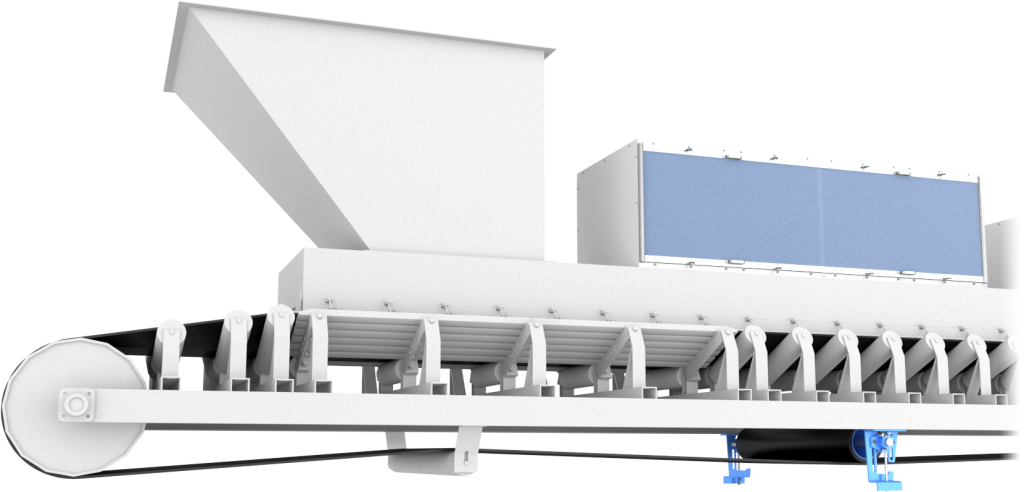

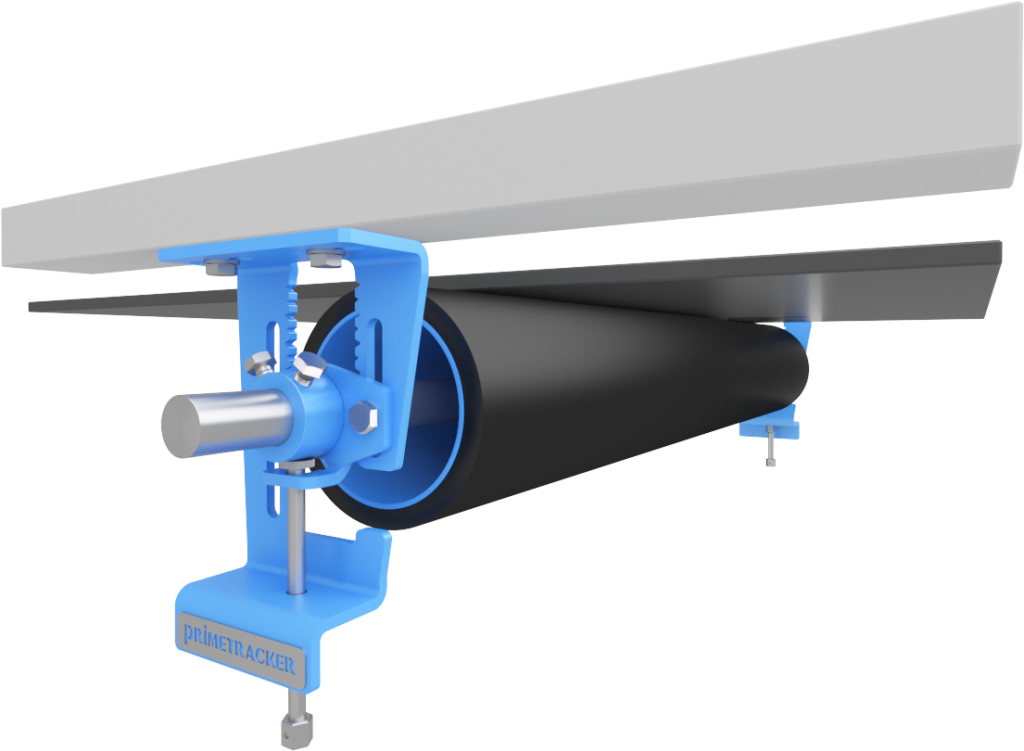

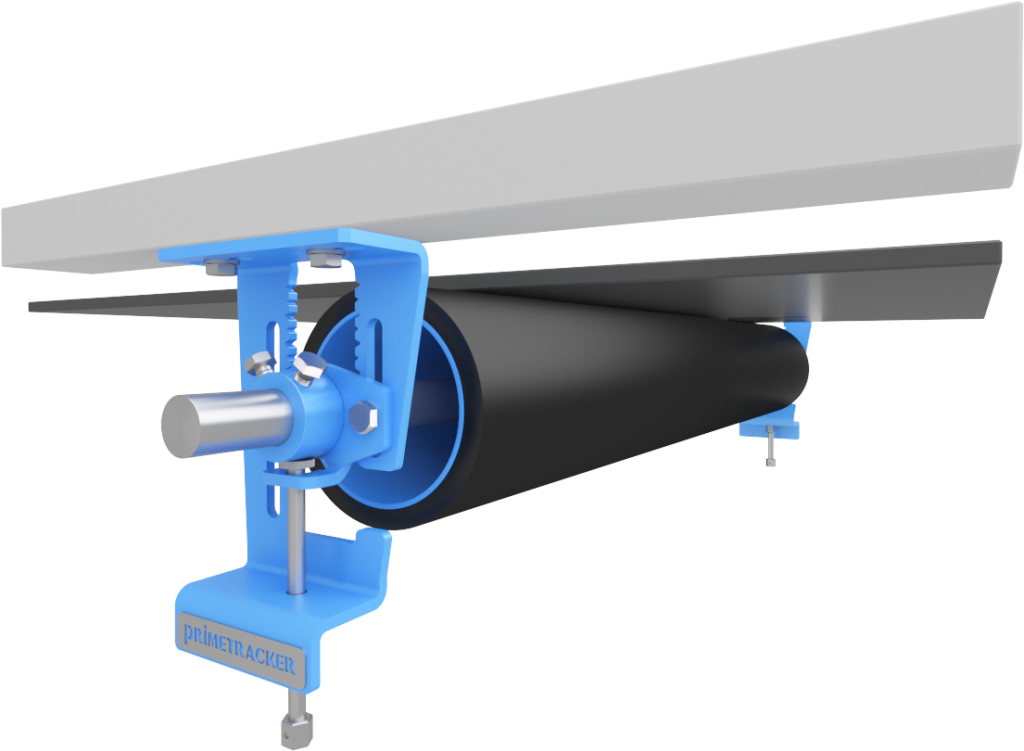

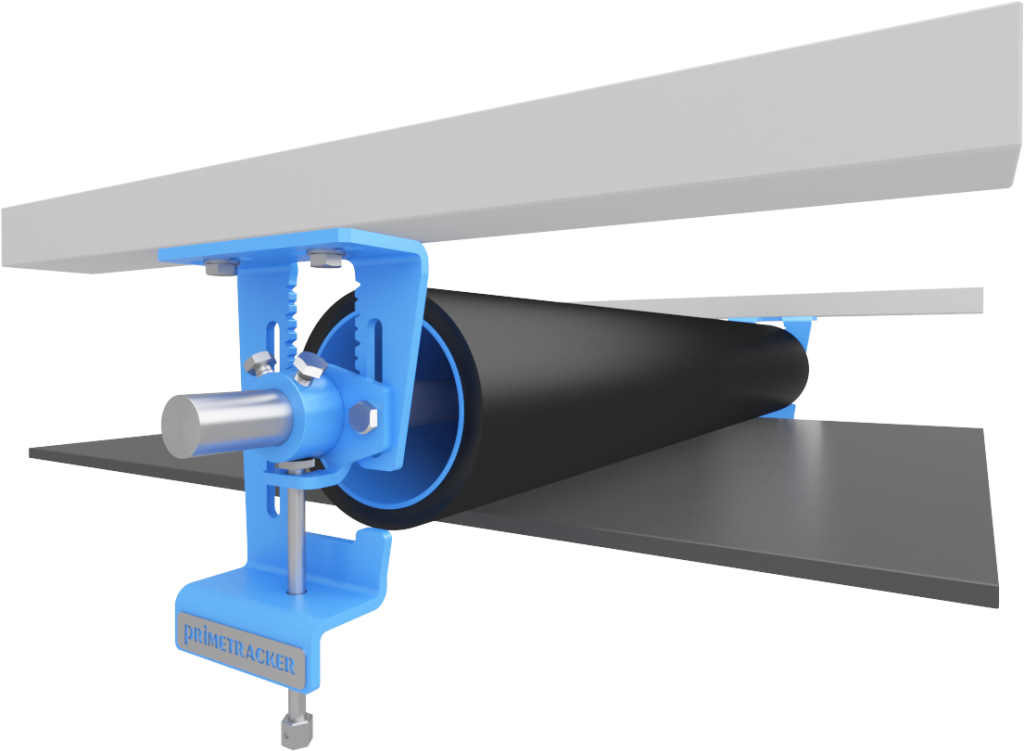

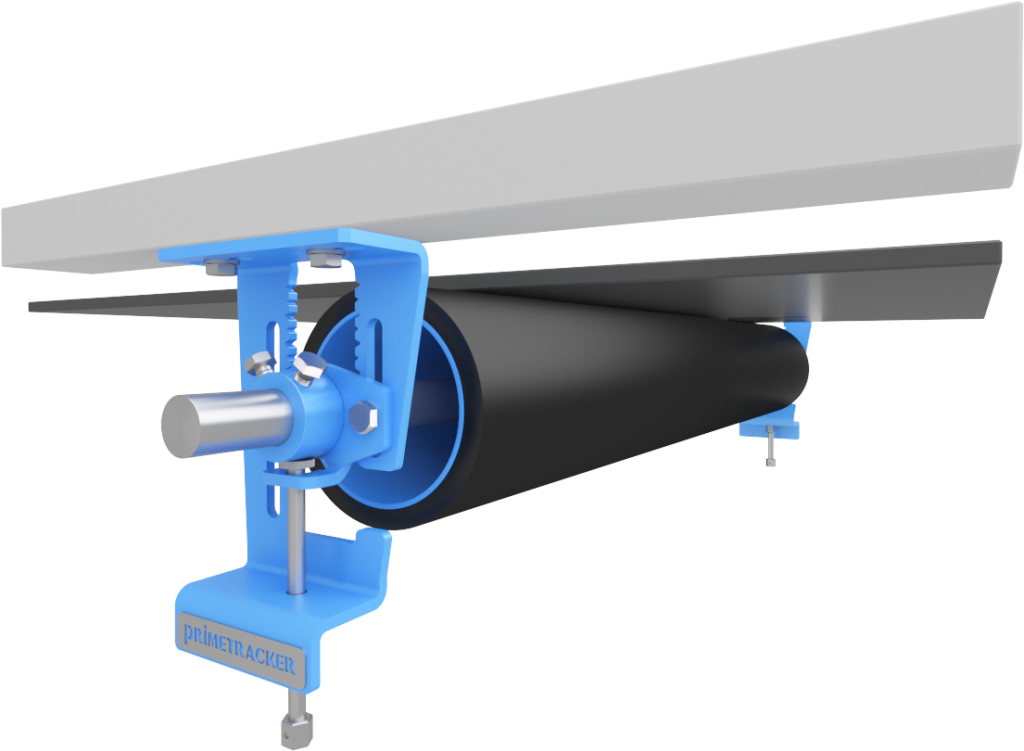

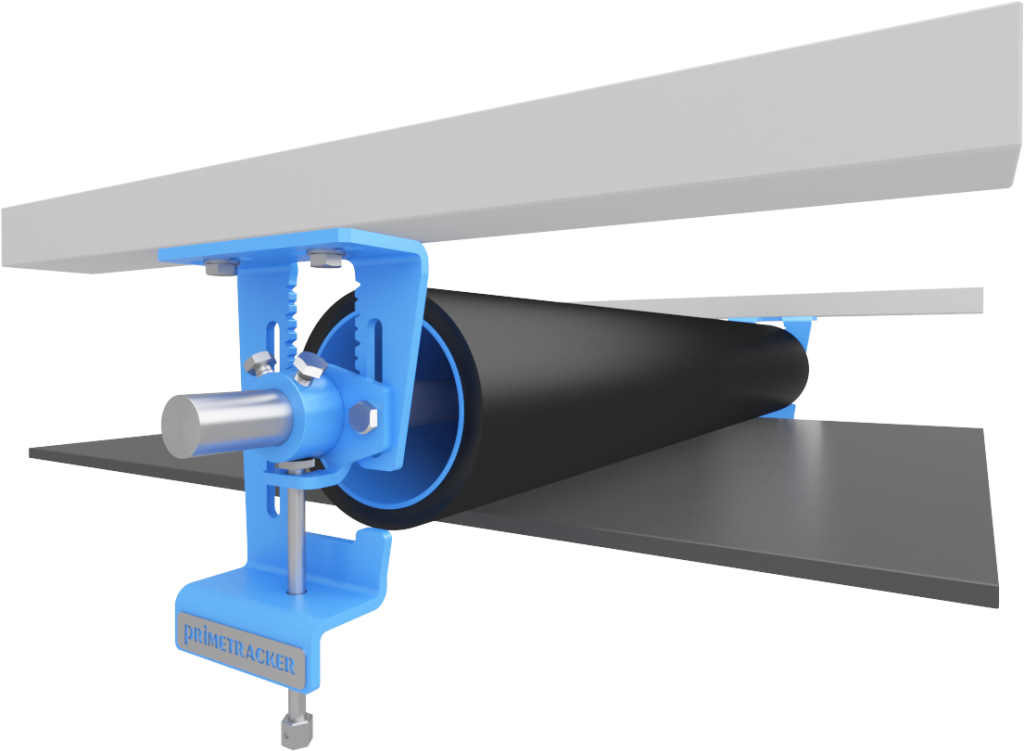

Installation in the lower belt

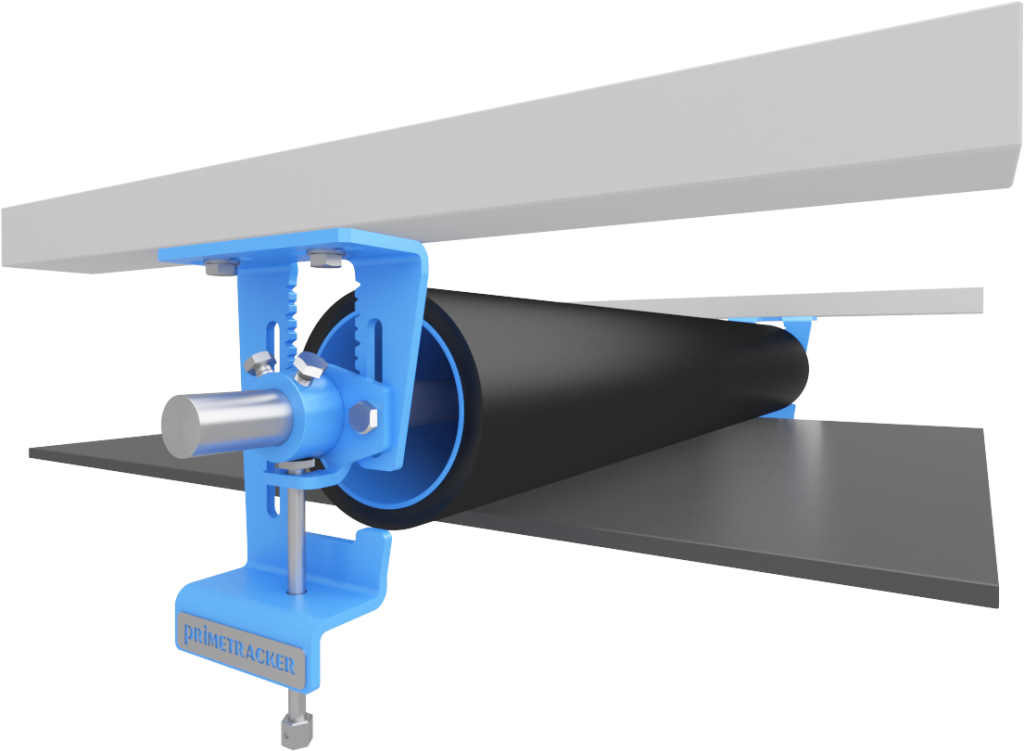

The PrimeTracker is installed in front of the return pulley with low pressure and at a distance of 3.5 x belt width. This system can be installed above and below the belt. It is preferably arranged on the clean side of the conveyor belt and is available for belt widths ranging from 500 to 2000 mm.

Below the belt

Above the belt

Installation in the lower belt

Below the belt

Above the belt

Below the belt

Above the belt

The PrimeTracker is installed in front of the return pulley with low pressure and at a distance of 3.5 x belt width. This system can be installed above and below the belt. It is preferably arranged on the clean side of the conveyor belt and is available for belt widths ranging from 500 to 2000 mm.

Masterly belt guidance

The new design concept provides the PrimeTracker with unique features. Due to its high mechanical sensitivity, the Tracker intervenes permanently and dynamically regulates even the slightest misalignment. On the basis of this principle, force-intensive belt deviations are avoided and intensive load torques for the conveyor belt are reduced in the long run. The PrimeTracker does not require any further auxiliary components, as e.g. side guide rollers or other guiding aids.

With comparably low costs, this highly efficient, maintenance-free and durable tool ensures smooth running of the conveyor belt. Furthermore, it reduces the risk of damage and helps to avoid belt repairs as well as costly downtimes.

Advantages

- The PrimeTracker immediately reacts already in case of the slightest off-centre running of the belt.

- It guides the belt with very low friction and small forces → long service life.

- It does not “wait“ for the guide roller to tilt vertically (like conventional conveyor belt tracking systems do), but reacts before.

- It also functions perfectly in reversing mode.

- Easy installation

- Maintenance-free

- Special pivot bush, very durable

- It guarantees optimum position at the conveyor transfer point. In combination with the AirScrape spillage is no longer possible.